Technology Roundtable: Drilling Contractors

1. How can you characterize the current state of the Russian drilling market and what is your forecast for 2018?

NSH ASIA DRILLING: A number of key factors affect the Russian drilling market today.

First of all, Vertically Integrated Oil Companies have established their own oilfield services divisions. Today around 90% of the drilling activities are carried out by 8 license holders, most of which use their own or contract affiliated drilling divisions.

The second factor directly resulting from this is a reduction in the drilling scope available for the rest of the market players.

The third factor is a reduction in the drilling scope due to oil production restrictions. I think that in 2017 the industry did not experience the effect of this factor to the fullest extent, but if the agreement is extended for 2018, the utilization rate of drilling rigs in Russia may decrease significantly.

SSC: The 2018 trends are as follows: 2017 showed clearly that drilling growth rates had slowed down, and in 2018, the mineral developers shifted their focus primarily to improving project efficiency. A change in the approach impacts the volume of services since the implementation of the lower efficiency projects is delayed. The OPEC-plus deal imposes further restrictions, and accordingly in 2018, we expect to see the meters of production drilling freeze at the 2017 level or even somewhat below.

IGS: In my opinion well-construction technologies are becoming more sophisticated. This trend has been observed during the past few years and 2018 will be no exception.

The wide application of new drilling technologies requires the use of state-of-the-art drilling equipment and I believe it will be the basic strategy of the oil companies in the nearest future.

Our company long ago switched to the application of high tech well construction technologies, namely, multilateral TAML3-5 systems, casing running systems, rotating cementing, casing drilling, composite centralizers to allow a reduction of the friction factor while running the casing, reaming turbo-shoes for casings, swivels for string rotation while running the liners, foam cements and DPM. Some of them were first applied in Russia.

PNG Drilling Company: Currently, the Russian drilling market is showing divergent trends. On the one hand, the operators, the major vertically integrated oil companies, are primarily pursuing exploration and production drilling. Bids for drilling services are regularly posted. On the other hand, the profit margin in the drilling business is extremely low, and earnings do not allow for extensive investments in the newest, last generation drilling rigs. While the price factor dominates the operator’s choice of the drilling contractor, the latter has no incentive to purchase and use cutting edge drilling rigs. The sector is moving towards low cost and cost cutting, while drilling efficiency remains sidelined. To this end, the profit margin of drilling services and the operator’s criteria when selecting a drilling contractor are, in my opinion, the key industry challenges.

Tatburneft: Currently, the Russian drilling market is steady. No significant drops or spikes have been observed. The future expectations for drilling activity are forecast to remain flat at its 2017 level.

Gazprom Burenie: Over the last 10 years, the volume of meters drilled has increased on average by 7 to 8% per year, due to a large extent to oil production drilling. Last year was no exception: according to CDU TEK, 28.6 million meters were drilled in Russia in 2017 (including both production and exploration drilling), while 2016 growth was 11%.

In the past decade, Russian drilling slumped twice – in 2009 and 2014. These were years of plunging oil prices, a period of uncertainty, but drilling returned to growth in the following year.

This year, oil prices will most likely stay range-bound at a level of $60 to 70/bbl. We do not foresee any collapse because the oil production cut deal was extended by Russia and OPEC to 2018. This may justify the assumption of maintaining the same drilling levels as in 2017 at least.

ERIELL Group: The market and competition ecosystem of this oil and gas service segment is gradually taking shape. At the same time, the majority of customers are raising their service quality standards and demand strict adherence to health, safety and environment procedures. Meanwhile, drilling will increase overall due to steadily growing oil prices.

2. The latest drilling analytical reports published in ROGTEC have shown that the trend in the next five years in Russia will be to construct complex horizontal wells and extended-reach wells. Have you observed these changes in your company? Does your company have all the necessary equipment to drill and bid for complex well construction projects?

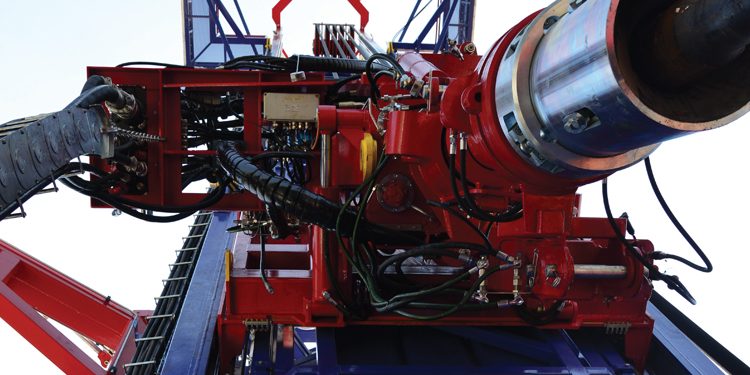

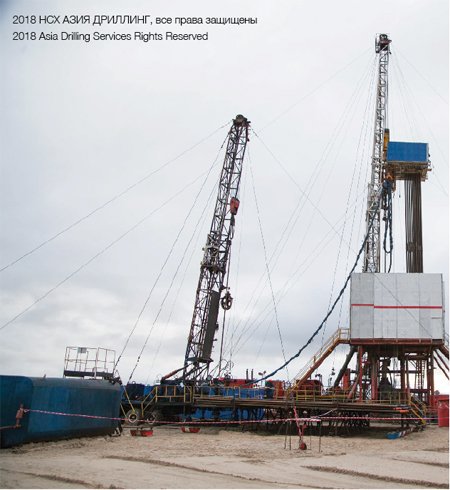

NSH ASIA DRILLING: Certainly the number of horizontal and extended-reach wells drilled is increasing. This leads to a toughening of the requirements for drilling contractors, primarily to personnel qualification and equipment. For example, in the Yamal-Nenets Autonomous District, most of the sidetracking was performed by drilling rigs with a capacity of 125-140 tons. However, since 2017 we observed a trend towards an increase in the number of tenders for sidetracking requiring use of the drilling rigs with a capacity over 160 tons. When choosing a development strategy, NSH ASIA DRILLING, takes into account the increasing complexity of wells. As a result, we enlarged our fleet of drilling rigs in 2014 and purchased five mobile drilling rigs with a capacity of 180 tons with the top drives for sidetracking projects.

SSC: In recent years, horizontal well drilling has been growing rapidly (in 2017, the drilled meters in horizontal wells accounted for 40.6% of total production drilling) but, in our opinion, the share will remain steady at 41 to 43% in coming years.

With regard to SSC capabilities, our company has everything required to drill horizontal well sections less than 1,000 m long (about 85% of the wells with horizontal section falls into this category). Equipment and technology provided by major international companies are required for the more complicated well profiles. However, this situation will gradually change as relatively new production companies begin offering pilot testing with their equipment. Clearly, not every endeavor will be completed but one thing is for certain – producers independent from the big four have sharply increased their equipment development efforts.

IGS: Investgeoservis has been operating in the Yamal-Nenets Autonomous District, Krasnoyarsk Region and Komi Republic since 2003. 90% of total number of drilled wells are high-tech, i.e. horizontal wells, including extended-reach ones with measured depth of up to 8.5km. Our company uses specialized drilling equipment and employs a fleet of heavy drilling rigs with capacity of up to 450t. We are definitely ready to offer the market our best experience and drilling equipment for well construction projects of any complexity.

PNG Drilling Company: I believe that the construction issues of horizontal and extended reach wells rest with the reservoir engineers. Reservoir engineers decide on a particular well path based on geological, lithological and other properties. However, we must also recognize that the horizontal well share of the total wells drilled by the PNG Drilling Company is actually rising.

Tatburneft: In general, there is such a trend, but we did not notice any major increase in the number of horizontal wells in our customers. There are wells for multi-zonal fracking and a number of individual projects with a high DDI, but over the past several years their number has remained constant. Our company owns the equipment required for well construction of any complexity including horizontal wells.

Gazprom Burenie: This trend has been strong over the past few years and will only go from strength to strength. The percentage of horizontal drilling increased from about 10% in 2008 to about 35% in 2016. Horizontal and directional drilling activity is expected to coincide by 2023/4. The primary growth drivers are: 1) Technical expertise (the so-called learning curve) and contractors’ accumulated competency in drilling such wells; 2) Extensive use of highly efficient equipment (DHM, RSS, MWD/LWD); 3) Beneficial pairing of horizontal wells and multi-stage hydraulic fracturing

Gazprom Burenie, LLC, has a long history of developing hard-to-access Achimov deposits in the Urengoyskoye, Novo-Urengoyskoye, and Vostochno-Urengoyskoye Fields; constructing production wells in the Russia’s largest discovered onshore fields, the Trebs and Titov Fields in the the Nenets Autonomous Area. It is also the only contractor in the Bovanenkovo Field. The company drilled 21 horizontal wells in the Termokarstovoye Field. The company also drilled the ERD wells in the Yurkhar Field.

One of the most complex and critical projects undertaken by Gazprom Burenie since 2011, is horizontal drilling in the Prirazlomnoye Field on the Arctic shelf.

ERIELL Group: Yes, we certainly have. ERIELL is focused on building complex horizontal wells. Indeed, our company was the first company in Russia to learn and implement extended wellbore drilling technology for the complicated Achimov deposits, and to prepare wells for multi-stage hydraulic fracturing, etc.

3. Do you agree that the Russian drilling industry is increasingly shifting from turnkey contracts to day rate contracts? What is your opinion and how does this affect your drilling operations?

NSH ASIA DRILLING: Key NSH ASIA DRILLING clients – Rosneft, Gazprom Neft and Lukoil – have almost completely shifted to day rate contracts. Ideally, this approach should imply that drilling contractors will be responsible only for the drilling crew and the drilling equipment performance, and all the issues related to the technology will be dealt with by the Client. However, given the high risks and increasing complexity of the drilled wells, drilling contractors have to take the technology in account. As a result, NSH ASIA DRILLING has established an R&D Center where highly qualified process specialists together with the Client’s representatives develop and assess the most effective well drilling technologies.

SSC: There is a clear trend toward separate services. The drilling contractor needs to quickly respond to the market changes. Does this approach serve its purpose all the time? In our opinion, there is no one-size-fits-all solution. Separate services and hiring the drilling contractor at a daily rate make absolute sense when constructing a large number of the same type of wells in a large field, if all process solutions have already proven themselves in the real world, and experience has been gained from the project. When drilling wildcat and exploratory wells and implementing new projects in a little known environment, it is far easier to contract turnkey since the large drilling contractor has the required expertise and often experience in different areas (and different environments) and assumes the project implementation risks. The same can be said for complicated drilling projects with expensive equipment when the risk of equipment loss may cancel out the benefits of separate services. This approach requires the establishment of an organizational structure in charge of the production and drilling contractor management inside the mineral developer company. This is not always cost efficient (for example, in case of little drilling, seasonal fluctuations, etc.). Therefore, while the percentage of separate services grows, there will still be a place for turnkey projects in the market.

This year, the SSC portfolio of projects is almost equally split between turnkey and daily rate. In the future, we plan to focus more deeply on each of these areas within the company.

IGS: Indeed, there is a market trend towards day rate production drilling contracts. This involves the willingness of the client to apply a quality process of well construction management, and to assume production risks and responsibility for the final result. In my opinion, such an approach is justified only if the client has many years of experience in well construction and if all technologies are proven on a single field. However general contracts are more appropriate for projects with a small scope of drilling or for independent projects. Our company possesses all the necessary production, labor and management resources to manage complex well construction projects on a turnkey basis. At the same time, we are market players and operate on any contractual terms offered by our clients.

PNG Drilling Company: Yes, I fully concur with this conclusion and can only welcome the shift towards providing drilling services on a daily rate model. It is beneficial for operators in that it allows them to generalize the well-targeting technology across the specific geological conditions, thus reducing the risks for individual wells. It is also beneficial for the drilling contractor since it removes the risks related to subcontractors, making it responsible solely for its own drilling rig and crew. Providing drilling services on a daily rate model also optimizes the drilling costs for the operator, since by purchasing a narrower service it is free from any general contractor’s mark-up by the drilling contractor. This saves 10 to 15% of the entire well cost.

Tatburneft: Clients want to do construction more cheaply and daily rate contracts let them choose the most suitable cost alternative by service type at any well construction stage. In the first stage, this shift can lead to a fall in the quality of services provided which later returns to normal.

Gazprom Burenie: We believe it is standard practice for the major oil and gas companies with the necessary competence to offer drilling and all related services for tender separately, within the familiar drilling environment where it is permanently located. However, the same companies are embarking on unique projects in the new provinces and exploration drilling under a turnkey contractual approach.

In the rest of the world the trend is reversed: companies prefer the oil service companies to implement turnkey or EPC projects, which allow them to considerably downsize in terms of their own highly qualified and expensive manning. This also empowers the general contractor to streamline the project solutions in order to cut costs. The leading market for the daily rate agreements is onshore drilling in the USA (the Contiguous United States also called the Lower 48 states) where high competition enables the expedient mobilization of contractors at the best rate. At the same time, offshore drilling services in the United States Gulf and Alaska are generally provided turnkey.

In 2017, our company drilled 1,119 thousand meters with 472 thousand meters drilled under a turnkey approach and 647 thousand meters drilled as a separate service. We also have an in-house production team with highly qualified employees which give us the capability to implement complex projects at the lowest risk for the customers.

ERIELL Group: This is a trend we have seen over the last two years. Most of the company’s drilling rigs today operate at a daily rate. My view is that this shift was unavoidable under the existing macroeconomic scenario. Sure, these agreements definitely have an effect on us. Meanwhile, drilling contractor’s finances have come under increasing pressure and the flawless operation of the drilling rig and its maintenance team and operation’s practices are gaining a greater significance.

4. The price of oil has strongly affected profits in the oil sector in recent years. Considering the current increase in prices and activity, is there a risk that, due to insufficient investments over the past few years, the oilfield services sector will not be able to participate in new projects due to a lack of opportunities and manpower?

NSH ASIA DRILLING: Despite the gradual increase in the oil price, the increase in drilling activities is constrained by oil production restrictions. At the same time, the risk of investment shortage remains as the complexity of the well design increases, which requires timely modernization of the equipment and technologies used.

In the current conditions, we do not observe a strong deficit of drilling rigs. However, the situation may change, if in 2018 oil production restrictions will be lifted. Probably, the deficit will not arise at once, but will grow within 3-5 years and the drilling companies will have little time to respond to the increased demand. True, only the most flexible companies capable of taking risks and reacting quickly to changes in the market will be able to do this.

SSC: In 2017, drilling rigs (mainly the echelon-type drilling rigs) were heavily utilized. If activity soars (which we do not expect in 2018), then heavy duty drilling rigs (both the train and modular type) with a capacity of 320 to 450 tons for production drilling and mobile drilling rigs with a capacity equal to or more than 200 tons will become in short supply.

The situation with manpower is even more challenging as the historically low wages in the oil service sector do not match the working conditions (strenuous physical work in any weather, continuous production) and have increasingly less appeal for young people. We see that a number of the service companies have started to bring in manpower from the nearby nations and Central Asia. However, we find such solution detrimental. Recruiting low skilled workers further skews the labor market, while at the same time increasing the occupational injury and accidents. The challenge faced by the oil service industry’s community is to demonstrate to the project owners that only highly skilled personnel is capable of dealing with the ongoing work efficiency issues.

PNG Drilling Company: It is true that such risk exists. We are faced today with a situation where a single drilling contractor participates in a bid and is awarded a contract. This limits competition and the quality of the drilling services provided. The profit margin of drilling services is obviously a growth engine for drilling contractors. Operators with a future are capable of meeting this challenge. It is neither easy nor fast to implement. Operators would assist the drilling contractors, if they chose contractors not only based on cost but also on evidence of technological sophistication and efficiency of the drilling rigs.

Tatburneft: The situation will not change for the oil service companies inside the oil operators. The independent oil service units may face challenges with the high technology projects that require expensive equipment. The government co-investment funding would open a path for development for this category.

Gazprom Burenie: The Russian oil and gas tax system is designed to translate any shift in oil prices, first and foremost, into changes in terms of contributions to the state budget and, to a lesser degree, the economy of oil and gas company production business. The more than 50% drop in oil prices in the latter part of 2014 was cushioned by ruble devaluation, in addition to a flexible tax system. However, this clearly impacted the budgets and plans of oil and gas companies which began to squeeze costs with oil service contractors being among the early casualties.

Yet now we see that drilling continues its growth trend. Wells are becoming more complicated, and the oil and gas company’s requirements are expanding as the daily rates freeze remains unchanged. This will eventually bears down upon oil service contractor profitability. With the lowest margin in the drilling business, purchasing new drilling rigs does not make any sense and investment does not pay off within a reasonable time frame. Today oil service companies are focusing their efforts on streamlining business processes and slashing costs to improve profitability.

In our view, the current situation combined with the aging drilling rigs will in the short term result in inadequate drilling capacity, as well as an escalation in daily rates that will enable upgrading and purchasing modern drilling rigs in line with the customer’s needs. However, before the market achieves equilibrium, supply will be short, and oil and gas companies will either have to pay an extremely high price for the rig or postpone brining new wells online until there is a vacant drilling rig. We see that customers are aware of the circumstances and can cite Rosneft, PJSC, as an example of developing an own oil service business to avoid any interruption to drilling programs and to support its needs to the fullest.

ERIELL Group: The oil service market is experiencing quite tight drilling capacity. Drilling companies need to invest in new equipment. A cooperative equipment investment program, together with the customer, within the frame of long-term agreements may remedy the situation. To our knowledge, some production companies are considering it.

5. The age, condition and limited capacities of the Russian drilling rig fleet have become a sore point for the region. Many rigs have been in operation for more than twenty years and need urgent replacement. Please describe the condition of your drilling rig fleet and provide feedback on the age and capabilities of the Russian drilling rig market in general.

NSH ASIA DRILLING: The problems of the aging fleet of rigs in Russia are quite acute, but not for NSH ASIA DRILLING. The 15 drilling rigs owned by our company are used in Russia. We specialize in drilling oil and gas wells and sidetracking using mobile drilling rigs with a capacity of 180-225 tons. All drilling rigs are equipped with foreign top drives. The average age of the drilling rigs is less than 6 years making us one of the leaders in Russia. Therefore, the drilling rig fleet condition is not a problem for us, but a competitive advantage.

Unfortunately, when bidding, some contractors cut prices by saving on the costs of maintaining the equipment in a working condition. Such companies can win contracts and start drilling but down-time for maintenance will be catastrophic. Earlier, when working on a turnkey basis, this entailed financial losses exclusively for the drilling contractor. However, when speaking of a day rate contract, drilling rig failure means downtime for service companies engaged in cementing, HDD, drilling fluid handling, etc, and it is the Client who pays in this case. In addition, long downtime increases the risk of well problems. Therefore, today, when participating in tenders, we see that Clients have become more focused on the age and condition of the equipment.

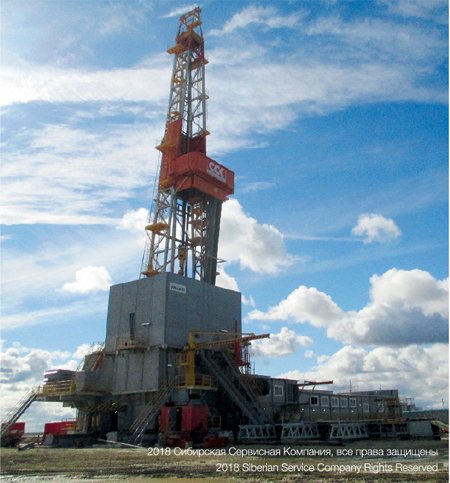

SSC: Today we own 65 drilling rigs. A further 15 rigs (23%) were purchased in the last 12 years. The rest underwent comprehensive retrofitting: switching to triplex plunger pumps, replacement of derrick headboards, and modifications for the top drives, etc. Capacity wise, there are 18 heavy duty (250 to 320 t) rigs, 40 medium duty (200 to 225 t) rigs, and 7 light duty rigs (including 5

mobile ones).

In an effort to move away from import reliance, SSC primarily uses Russian-made, both new and retrofitted, equipment. We have 7 Chinese drilling rigs: they are mainly mobile drilling rigs. We aim to further pursue our equipment retrofitting strategy.

Regrettably our proposed program to recycle old drilling rigs (providing compensation for retired drilling rigs when the new Russian equipment is procured) has never been established, since it would provide momentum to upgrade the Russian drilling rigs and put all the remaining Soviet legacy equipment out of production.

IGS: Our fleet of drilling rigs is fairly young. The average age of the drilling rigs is 10 years. Speaking of the Russian market, the majority of the drilling rigs are overaged. Drilling companies need to make capital investments to renew their drilling fleet, if they plan to develop new fields. The opportunity for upgrading equipment by the drilling companies largely depends on the pricing policy of the clients in the drilling market and the long-term nature of well construction contracts.

PNG Drilling Company: The age of the drilling rig is a key issue for the sector. I am pleased to say that the PNG Drilling Company is the industry leader in terms of drilling rig age. The average age of our drilling rigs is 2 to 3 years. This is because PNG Drilling Company started from scratch without any old Soviet drilling rig legacy. Today we have 10 mobile hydraulic no draw-works drilling rigs operating in Russia. The capacity of our drilling rigs ranges from 1,260 to 2,250 HP, and they can operate both in the Extreme North (Gubkinsky, the Yamal Nenets Autonomous District) and European Russia. All of our drilling rigs are made in Italy and are classed 5th (latest) generation. The PNG Drilling Company has prepared a slide show named PEAK 16 after the number of the major, key advantages of the PNG Drilling Company’s mobile drilling rigs compared to the conventional drilling rigs with draw-works employed in Russia by other drilling contractors. The PEAK 16 slide show is available on the PNG Drilling Company’s website at www.png-drilling.ru.

Tatburneft: We have been retrofitting and upgrading our drilling rigs starting from 2015. Today we purchase drilling rigs based on the current customer’s needs. We are aware that drilling conditions and technology change, so we appreciate it when customers define lots up for bid, taking into consideration the time required for the contractor to procure (purchase) equipment for a specific project. However, it is also clear that the most sizable competitive advantage belongs to the big vertically integrated companies owning their own drilling unit.

Gazprom Burenie: Russia has about 1,200 to 1,300 drilling rigs in operation. Slightly over 40% of them are more than 20 years old and they will be either retired in the next five years or will require costly overhaul. Today the utilization of the most efficient, state-of-the-art heavy duty train type rigs, is getting close to 100% with only classic single well drilling rigs on standby.

Over the last decade, Russia has annually purchased about 65 drilling rigs on average. This number is adequate to meet growing market demand. In coming years, we expect further drilling growth mainly supported by an increase in an average well length (with a growing share of horizontal wells) that calls for new higher capacity drilling rigs.

Over the next 2 to 3 years, we may face a situation where a sizable part of the aging drilling rigs will be retired but the growing drilling activity will require new drilling rigs. As described in the question above, investment in new drilling rigs does not pay off at the current daily rates and this may lead to short supply and soaring daily rates.

We are a major drilling contractor in Russia with 153 drilling rigs. The majority of our drilling rigs are the most popular, heavy duty drilling rigs with a capacity over 250 tons. Over the last 7 years, the company has invested 15 million rubles in upgrades. We have procured 27 new drilling rigs and retrofitted 19 drilling rigs. At least four BU-6000/400 rigs are scheduled for purchase in 2018. Over the coming 10 years, we plan to purchase at least 3 to 4 drilling rigs annually.

ERIELL Group: Yes, this issue regularly comes up in discussions with customers. One of ERIELL’s competitive edge is its newer drilling rigs. At the same time, we are continuously retrofitting obsolete assemblies, and replacing and repairing smart units (the top drives, diesel generators) in our drilling rigs.

6. In his recent interview with ROGTEC, Aleksei Cherepanov from Gazprom Neft cited the example of the huge difference in the mobilization period of drilling rigs in Russia and abroad. He said that in Russia it takes about 30 to 45 days, while in international practice this period is about 10-15 days. What are the reasons and what needs to be done to optimize and shorten the time of drilling rig mobilization in the region?

NSH ASIA DRILLING: Unfortunately, the technical and technological gap between the oil and oilfield services companies in Russia and certain Western countries is still quite wide. Such a difference in drilling rig mobilization period can be caused by a number of factors, including: weight and dimensions of the drilling rig, the conditions of the roads in the field, the availability and technical condition of special machinery, etc.

When working in the Khanty-Mansi Autonomous District, NSH ASIA DRILLING relocates a single drilling rig over 20 times. To reduce the relocation period, our company has developed a transportation plan for each drilling rig type detailing the work sequence: list, number and time of machinery arrival and personnel involvement at every stage. These plans allow us to minimize the time losses when relocating the rigs and, as a result, we are able to relocate equipment much faster compared to the standard period.

SSC: It is necessary to factor in differences in the drilling rig design when comparing installation time. Since Russia uses mainly the heavy duty echelon type drilling rigs while other countries employ modular rigs with greater installability. For example, the heavy duty drilling rigs in the Gulf countries are shipped upright only slightly disassembled and installed within 3 to 4 days. What can be done in the desert is not possible under the axle weight limits and maximum dimensions when moving along the Russian federal highways. However, there is clearly room for improving installation time. We know from our own experience when, in summer 2017, the ZJ-50 echelon type drilling rig was dismantled, shipped and installed in 25 days. The key element to this success is the activities were performed in line with the procedures developed together with the project owner.

IGS: First of all, the period for mobilization in Russia depends on such factors as field remoteness from well-developed infrastructure, independence of projects, road quality, and seasonality of road and river crossing operation. To mobilize rigs in these conditions, a large number of auxiliary machinery is required: all-terrain vehicles, low-bed trucks and semi-trailers, truck cranes for loading and unloading, mobile steaming units, etc. All this affects the term of equipment delivery to the field.

Another important factor impacting the term of disassembly, transportation and installation is drilling rig design. With modular design, widely used abroad, rig assembly is much faster. All drilling rig modules are in fact independent, connections are quick release, pump unit and mud handling system are skid or container mounted allowing quick loading. Equipment is transported on trucks applying self-loading method (loading using own winch).

To shorten the drilling rig mobilization term in the region, it is necessary to apply modular design and to improve the quality of mobilization planning and management considering unbiased difficulties of transportation in the Arctic.

PNG Drilling Company: Russian drilling contractors are really lagging behind their North American counterparts with regard to mobilization time. There are several reasons for it.

The first group of reasons is related to organizational and regulatory matters. The procedures to mobilize and bring the drilling rigs into operation differ between North America and Russia. In Russia, we have to go through extensive red tape to obtain permits from the agencies of the Ministry of Internal Affairs, if we want to haul an oversize load and pay a charge for the use of roads (Platon, etc.). Roads, bridges, and other infrastructure in Russia impose substantial restrictions on the drilling contractor, such as maximum axle weight for trailers carrying drilling rigs, the load size, etc. We have to break down the load into several smaller shipments. Our operators have a huge number of standards and procedures for drilling rig start-up and pre-start-up inspection. The number of such standards and procedures is multiplying at a fast rate. Gazprom Neft, PJSC, has its Top 12, Top 5, etc., and NK Rosneft has its own standards, requiring a large number of preparatory activities, such as electrical, mechanical, cable pulling, etc. inspections by the drilling contractor. There are even some procedures related to the drilling rig “backyard”. At the same time, as far as I know, in North America, the drilling rigs move without shutting down the boilers and oversize loads cab be moved without lengthy permit procedures.

The second group of reasons is financial. The drilling contractor’s mobilization rates are part of the lot bid price used to determine the winner. In order to reduce the lot bid price (which sadly becomes an end in itself), the drilling contractors slash the mobilization and demobilization rates sometimes even below cost. And then at a minimum budget, the drilling contractor tries to pay for the drilling rig mobilization to a new drilling location. Consequentially, to meet a clearly too low mobilization budget, the contractor has to cut back on everything: the number of cranes, lowboy trailers, other vehicles, and manpower.

These, I think, are the key factors why the Russian drilling rig mobilization time is lagging behind the best global practices.

Tatburneft: Comparing Russian and global practice may be a flawed idea. This is due to the dissimilar conditions including the requirements to transport infrastructure and hauling. Further, there is ample room for improvement in logistical issues such as early cuttings removal, access road preparation, etc. These are thing which are not always readily paid for by the customer. Emergence of competition in the service market within this category and the customer’s willingness to pay additional cost to expedite mobilization will cut down the mobilization time.

Gazprom Burenie: We share Mr. Cherepanov’s analysis: mobilization time in Russia is significantly longer than the mobilisation of a foreign drilling rig. However, we should bear in mind that these drilling rigs cost much more than the rigs operated in the Russian market. They, accordingly, have greater maintenance costs and, as a result, higher daily rates.

Our company has initiated a high-tech drilling rig project and we have made some progress which will benefit domestic projects. Is the customer willing to pay for it?

ERIELL Group: This is mainly a matter of infrastructure: permanent roads, heavy haul vehicles capable of moving the drilling rigs slightly disassembled or complete drilling derricks vertically, for example. There is complete awareness about this in Russia. Even 30 to 45 days in the High Arctic tundra, bogs, snow, and impassable roads can be a challenging time frame for us.

7. There has been a large number of accidents in the regional drilling sector when it comes to HSE. What measures are being taken to improve the HSE standards applied during drilling operations with a view to preventing accidents, including fatalities?

NSH ASIA DRILLING: Compliance with HSE policy and improvement of the HSE requirements has always been and will always be a priority for NSH ASIA DRILLING. Not a single fatality has been registered throughout the existence of our company. However, the company strives to continuously improve the safety policy. For example, one of the key clients of our company initiated a global program to improve safety levels. Despite the material costs required, we decided to implement this program at all NSH ASIA DRILLING sites. Thus, any initiative aimed at improving the work efficiency is first carefully evaluated by the expert commission, then tested in one or several crews, and, if recognized successful, implemented throughout the company.

SSC: I would like to clarify that OHS performance of the drilling companies is far better than that of the subcontractor companies (shipment, rig-up operation, power supply), which are mainly small companies or even sole proprietorships. The central challenge in this case is not developing new, improved standards but retaining the highly skilled workers on the project. Because only they offer a hands-on approach to remove the risk factors in good time rather than to respond to what is happening. While the major tool of applying pressure on the contractors so far has been the audits and penalties (and the potential of this instrument is on the verge of becoming exhausted), today a number of project owners perceive the need for new approaches to OHS. The case of Gazprom Neft may serve as an example of how much time and effort is required to cooperate with contractors on tactics to promoted safe production with workers. Retaining highly skilled, well-trained workers at the Gazprom Neft’s production facilities is kept visible on its list of priorities.

IGS: A high level of danger has always been a typical feature of the oil and gas industry. Our company’s management is fully aware of its responsibility for quality and HSE. Understanding that these processes are an integral part of a unified system and proper coordination of such processes has allowed us to increase the effectiveness of the work carried out and efficiency in achieving the objectives set. The company is constantly working to identify external and internal factors adversely affecting the ability to achieve desired results in the HSE field. By updating existing and developing new corporate standards the company has streamlined the processes of incident reporting, identification of existing risks and improvement of the employees’ competency.

PNG Drilling Company: Of course, the PNG Drilling Company places health and safety of people and environmental protection as its highest priority. None of our drilling rigs have draw-works, people on the derrick floor, derrick men, or steel ropes in the block and tackle. The drilling rigs that we use are the safest in the sector.

At the same time, it seems to me that the safety policy of the mineral developer operators requires some fine-tuning. What do I mean by this? The number of operator’s health and safety standards and procedures is growing. Sometimes, operators impose penalties on the drilling and other contractors for minor failings. Every day dozens and hundreds of the operator’s staff are involved in working on it. They have to develop special guidelines, procedures, impose penalties, involve private security companies and drones in monitoring the contractor’s activities, etc.

The number of accidents is, unfortunately, on the rise. There is clearly something wrong. There is a need to to re-assess, re-visit the trajectory of the mineral developer’s health and safety policy. This task and responsibility rests with the operators.

Tatburneft: Beyond the human component, a primary hazard in the drilling sector is posed by technology. This is, in most cases, a consequence of worn equipment. We emphasize monitoring and prevention by introducing a range of equipment maintenance and employee training programs and automating the processes connected with safety.

Gazprom Burenie: The risk of injury will be eliminated by completely excluding people from the process. However, today this is not feasible and, as a consequence, accidents occur. We carefully pinpoint their causes, in order to develop corrective and preventive action plans.

Our ultimate goal is zero injury. To this end, we have put considerable efforts into preventing injury, implementing and developing risk management procedures. We are continuously improving employee skills, replacing and retrofitting drilling rigs by introducing new safety systems. We are automating the process, and providing employees with modern safety clothing, shoes and personal protective equipment.

ERIELL Group: Height, heavy machinery and equipment, high pressure, and ice are major risks not only for the drillers. Our company is no different in terms of the most salient questions concerning our industry. We emphasize employee safety also through close partnership with our customers. We are implementing the 5 Steps system with workers and the middle-level engineers and technicians and developing leadership behavior in management with the appointment of a full-time HSE professional assigned to each drilling crew having. This has produced tangible positive results. This year marks the 10th anniversary of ERIELL in the Russian market. We have the benefit of the experience of working with all the major oil and gas companies. They many years ago identified occupational safety as an essential drilling contractor selection factor. ERIELL has an in-house drilling rig worker training facility. Health, safety and environment are our top priorities in the daily routine.

8. The pricing policy for the drilling projects is a major problem in the oil sector. Recently, the international media proposed an oil price tracking coefficient in which contract price increases in line with oil price increase. What do you think? Are there other solutions that would allow contractors to also benefit from an increase in the oil price?

NSH ASIA DRILLING: This proposal is quite interesting, but from my point of view, there is not a high probability of its implementation. After all, in order for this system to be fair the formula should account for the national currency to dollar exchange rate fluctuations, domestic inflation in the country and many other factors. Whereas the very idea of provisioning the possibility of price changing in the medium-term contracts is, of course, correct.

When participating in tenders, NSH ASIA DRILLING applies producer price index (PPI) to plan cost escalation for three years. This is actually inflation, but calculated not on the basis of the market basket, but based on the rise in the cost of capital goods and services. Since the annual increase in the POL and transportation costs is obvious, we believe that the annual price escalation considering PPI is fair.

SSC: The pricing policy for Russian drilling projects is not the major issue of the oil industry since all prices are fixed in rubles and have remained steady over the last few years. No further arrangements are necessary because the dollar exchange rate almost perfectly follows crude oil prices. The reasons behind the challenges faced by the oil service sector lie entirely inside Russia and are connected with the large project owners ruling the market (in 2017, four largest project owners accounted for 85% of drilling) and a plunge in the open market share in recent years (the scope put up for competitive quotations or bidding). Independent companies are attempting to heighten awareness among the mineral developers that reducing competition and reallocating activities to their own (in-house) service departments is detrimental to efficiency. SSC advocates a narrow niche and focus, along with intense competition in such a way that our own process departments provide 50% of their services to the outside partners and our drilling departments engage the outside production companies. Efficiency is always at the forefront of the agenda.

IGS: We consider linking of the well construction pricing system to oil price as a good opportunity for oilfield services companies to upgrade the drilling rig fleet when oil prices rise. We believe that clients would also be interested. After all, one of the bidding conditions set by the clients when purchasing well construction work and services is the use of new drilling rigs not older than 5 years in the field.

PNG Drilling Company: Daily rates in Russia are among the lowest in the world. We are capable of competing with the Chinese drilling contractors also, and are quite successful at this. They enjoy easy access to Russian bids but cannot operate at our rates for financial reasons. I don’t know whether to be proud or worried about this.

I believe that daily rates must be raised. Otherwise, Russian drilling contractors will have no avenues for development, and they will not be able to purchase new drilling rigs or spare parts to operate the current drilling rigs.

Tatburneft: Drilling costs and oil prices do not correlate linearly. As I see it, any agreement with an oil company works against the drilling contractor, unless they are an oil company’s subsidiary. Theoretically, the market adjusts everything: an increase in oil prices encourages the oil companies to expand drilling (apart from any production restrictions by the government).

Gazprom Burenie: Gazprom Burenie’s agreements are not directly linked to oil prices. Imported equipment and high technology services of international companies are used and accordingly, drilling prices depend on the dollar exchange rate.

Since the dollar exchange rate and oil prices in Russia are closely related, drilling costs may be tied to oil prices. In general, we believe it impractical to link the agreement value to oil prices.

ERIELL Group: It is an interesting proposal that needs to be considered closely. The mechanism to implement it is not yet clear. Contract value may change with the energy forecast. We would support this move.

9. What strategies or cooperation principles has your company applied in the aims of optimizing drilling operations and to improve KPI?

NSH ASIA DRILLING: Improving the efficiency of any company is always a complex process. NSH ASIA DRILLING has identified 3 main vectors of improvement. These are the development of personnel, reduction of downtime, and introduction of the state-of-the-art technologies. Each vector involves a whole set of activities. For example, NSH ASIA DRILLING has introduced and recognized an effective and prompt downtime notification system. Information on equipment failure is promptly communicated from the drilling site to the head office of the company, the cause of the failure (faulty workmanship, improper operation or untimely replacement / maintenance) is identified and appropriate decisions are made to prevent the recurrence. This may involve replacement of the equipment supplier, additional personnel training, etc. And the period from the downtime occurrence to the decision making is usually not more than a day.

NSH ASIA DRILLING is also currently actively evaluating the possibility of introducing the so-called Internet of Things concept into the production process in the framework of the company’s digitization project. This is a very promising direction, and we believe that it can significantly improve the efficiency of the company.

SSC: We perform best on the projects under ong-term agreements. Moreover, the key element to success is combining forces with the project owner, continuously improving efficiency.

IGS: Several years ago we began applying a project-based approach in drilling management to minimizes costs and allow drilling in regions under a variety of conditions. The development of the new system was dictated by an increase in the work scope and start of operations in the regions technically complex for commercial development. The introduction of the system resulted in a reduction of costs and downtimes, as well as an increase in the schedule speed and cost-effectiveness of projects.

PNG Drilling Company: The drilling contractor management should always think about ways to make operations more efficient and increase the profit margin for processes. Those who manage will have a bright future. The PNG Drilling Company is doing its best to meet these challenges.

Tatburneft: At the moment, we are pushing the well construction processes in our area closer to their technical limit. We are also implementing the Management System Transformation Program at the organizational level, at the core of which is business process disentangling and streamlining, followed by a comprehensive digital transformation. An integrated process model which we created is being used to regulate activities, allocate responsibility and authority, and improve the organizational structure and employee motivation system.

ERIELL Group: In order to boost efficiency, we are continuously improving well construction technology programs, accumulating and studying oil field experience while striving to utilize the available drilling tools and equipment prudently. By and large, a suitable agreement with the customer and reliable employees at each level of the organizational hierarchy are crucial factors.

10. Could you briefly describe the history of your success in the region

NSH ASIA DRILLING: In 2014 NSH ASIA DRILLING decided to develop the sidetracking area. During the first year in the Yamal-Nenets Autonomous District, the average sidetracking period constituted 37 days. In 2016, the technologies developed by the company enabled us to reduce the average cycle to 30 days, and in 2017 – to less than 24 days. Thus, we managed to reduce the drilling period by more than one third over a period of 4 years!

As a result, Gazprom neft rated NSH ASIA DRILLING as the best sidetracking contractor in 2015-2017. As for production drilling, the company set a daily drilling record three times in 2017. Last but not least, the company is recognized as an Eco-Leader and the best contractor in terms of industrial safety.

And we intend to go further. Success for us is just an impulse for further development: improving the quality of services and, as a result, increasing the efficiency of production processes.

SSC: In 2017, we scored several record highs in the Upper Salym Field (with Salym Petroleum Development as the project owner). As I mentioned earlier, the ZJ-50 drilling rig was mobilized and installed in the shortest possible time. In 2017 we also drilled the record 1,251 meters in one day in the Upper Salym Field, Cluster 123, Well 24-007.

IGS: The construction of high-tech wells of any design and purpose is what we are really proud of and we are ready to offer our client many years of experience in this drilling segment.

PNG Drilling Company: The PNG Drilling Company operates both in European Russia and in the Extreme North. In any of our operation locations, we strive to be the contractor of choice for our customers. We have succeeded in this, as far as the number of contracts awarded by major Russian oil companies and their positive feedback on our performance. We are proud of our clients’ high appreciation of our efforts and aspire to be even better, and even more efficient to exceed their expectations day after day.

Tatburneft: We have achieved good results in the construction of laterals in the Devonian terrigenous deposits. We have cut horizontal well construction time by nearly half, and we are continuously improving well construction technology and time for the bituminous deposits. Over the past two years, we have been constructing wells for Tatneft, PJSC, within an infill production project. The project is aimed at putting low profitability wells into development by reducing their costs as low as possible. This is accomplished by selecting the basic, trouble-free wells that support a slim design and a straightforward drilling technology. This way we were able to drill 7 wells with one crew in a month. When drilling such wells in November 2016, we beat a monthly record of 5,083 meters drilled in our area that was set in 1986 and took it even higher to 7,232 meters in November 2017.

ERIELL Group: I want to highlight our achievements in developing the hard-to-produce deposits in the Achimov formation of the Urengoy Oil and Gas Condensate Field. These are the longest horizontal wellbores drilled by ERIELL in the shortest time with hardly any competitors in this segment. I want to further highlight our high efficiency, for example, in such fields as Samotlor that require both a high drilling rate and rig-up speed. Also a major achievement is the company’s proficiency in mobilizing huge resources within a short time. To give just one example, we mobilized as many as six drilling rigs in the East Messoyakha Field within one winter.

11. Any further comments?

Tatburneft: The government incentive system for the drilling contractors to retrofit their equipment would move us to a new level in our search for customers, safety improvements, and achieving alignment of the occupational environment with global standards.

ERIELL Group: In the run-up to Geologists Day (April 1), I wish all drillers, both colleagues and competitors, the best of Siberian, health, a marvelous sense of humor, endless good luck, and, of course, may your home always be filled with warmth and comfort.

Andrey Tischenko

NSH ASIA DRILLING

Andrey Tischenko has worked in the oil production industry for over 20 years beginning as a well servicing rig operator in 1996. He has also worked as Lead Engineer in the oil field process department, Lead Process Engineer and as Production Service Development and Coordination Department Head. In 2012 he took the lead in and contributed to the success of the oilfield services company South-Eastern Service Group LLP specializing in well-servicing and workover. Andrey Tischenko has held the position of NSH ASIA DRILLING Director since 2016.

Alexey Kanashuk

Siberian Service Company (SSC)

Alexei Nikolaevich Kanashuk, Deputy Director General for Marketing in Siberian Service Company, JSC. Alexie has been working in the industry since 1994. He took the position of Deputy Director General for Marketing in Siberian Service Company, JSC in 2006.

Area of expertise: Member of Energy Strategy and Fuel & Energy Sector Development Committee in the RF Chamber of Commerce and Industry; member of the Advisory Board for Interface between the Oil & Gas Companies and Allied Industries under the State Duma Energy Committee.

Education: Kuibyshev Technical Institute, Moscow State Institute of International Relations, EPP (Calgary, Canada)

Alexander Kosov

Investgeoservis JSC

Alexander Alexandrovich Kosov graduated in 1992 from the Tyumen Industrial Institute, Oil and Gas Well Drilling Faculty. He started as an assistant driller and worked his way up the career ladder. He has held senior positions in Sibneft-Noyabrskneftegas JCS, Sibneft-Drilling LLC, Sinteco LLC, Integra LLC, Smith Production Technology LLC. Currently Alexander holds office of CEO in Investgeoservis JCS and is responsible for company’s core business management and control.

Zamir Abdullaev

PNG Drilling Company

CEO for PNG Drilling Company, LLC, from 2008 (since company inception).

PhD in Law. Two degrees in Military Law (Russia) and Oil and Gas (Russia and Great Britain).

From 2000 to 2003, he chaired the Board of Directors for Goloil, Siberian Texian CJSC (Khanty-Mansiysk Autonomous District), a Russian American oil producer company, recognised as the most efficient oil producing company in the Khanty-Mansiysk Autonomous District (Russia) with a maximum annual production of 1 million tons of oil.

Served on the BoDs for several German and Canadian oil and gas companies.

Honored with government awards, the Russian Governor’s Certificates, and the Russian Ministry of Energy’s Merit Citation and Certificate of Recognition.

Lenar Nazipov

Tatburneft Management Company, LLC

Born in 1978 in the industrial community of Nizhnyaya Maktama, in the Almetyevsk Area of the Republic of Tatarstan. He earned degrees at the Almetyevsk Oil Institute in Mechanical Engineering Technology and the Oil and Gas Business Institute.

In 2000, he began his career as an Engineer for the Almetyevsk Main Oilfield Equipment Maintenance Facility in Tatneft JSC. In 2002, he was appointed Deputy Chief Engineer in Quality, and Quality Control Manager, for the above company. First Deputy Chief Executive Officer in Production, Chief Engineer, for Tatneft-RNO-MechService, LLC, Deputy Chief Executive Officer in Production System Development from 2006 until 2009.

In 2009, he became head of TMS Drilling Service, LLC, within TMS Group Management Company, LLC.

In 2011, he was appointed Chief Mechanical Engineer, Mechanical Manager for the Production Department of Tatneft, JSC. First Deputy Chief Executive Office in Production Engineering and Development for TagraS Holding, LLC, from 2012.

He has been Director of Tatburneft Management Company, LLC, since 2015

Konstantin Galanov

Gazprom Burenie, LLC

Konstantin Nikolaevich Galanov is the Deputy CEO for the Strategic Development of Gazprom Burenie, LLC.

He earned a degree in Oil and Gas Field Development and Operation at the Samara State Technical University in 2002. He began his career as an Oil and Gas Production Operator for TNK-BP and later joined Smith Production Technology, LLC, serving as Project Manager. He was involved in a well construction project in the offshore Urumako I area in the Bolivarian Republic of Venezuela.

Has been with Gazprom Burenie, LLC, since 2011.

Vitaly Dokunikhin

ERIELL Group

Vitaly Borisovich Dokunikhin, CEO for ERIELL Neftegazservice, First Deputy Chairman of the Board for ERIELL Group.Vitaly has more than 10 years of management experience in oil and gas companies.

COO for ERIELL Group from October 2012.

CEO for ERIELL Neftegazservice since November 2015.