Technology Roundtable: Extended Reach Drilling and Sidetracking

1. With sanctions impacting on the region´s horizontal drilling in unconventional field, what is the current level of demand for horizontal and ERD wells? What projects are you currently working on?

Halliburton:

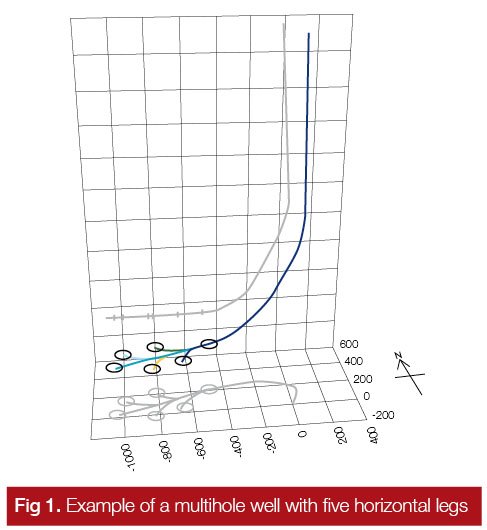

Currently, the demand for horizontal directional drilling has not reduced; instead, it has increased significantly. Horizontal drilling, overall, is more efficient and cost effective than vertical or slant wells once the well comes online. As a result, customers plan to drill more complex three-dimensional (3D) horizontal extended reach drilling (ERD) wells using advanced directional drilling technology, which Sperry Drilling is able to provide. Also customers increasingly realize the benefits of drilling multilateral horizontal wells strategically placed within the target reservoir, an area where Sperry Drilling has become a market leader, not only in Russia but also globally. Specifically, in Russia, Sperry Drilling has successfully completed wells of between three to five horizontal legs (Fig. 1) using openhole sidetracking to a total length of greater than 2,000 m.

C.A.T.oil AG: So far, we have not undertaken non-conventional oil and gas drilling projects. However, volumes of conventional drilling for our clients are increasing annually. Two thirds of the wells drilled by C.A.T.oil AG are horizontal. The capacity of our drilling rigs enables us to drill wells with vertical deviation of up to 2000 m. This gives us the opportunity to implement the majority of the projects offered by our clients. Last year we increased our capacity to 15 mobile drilling rigs. All the rigs have top drives with 200 tonne capacity. Most of the rigs operate in Orenburg Oblast but we also have projects in Western Siberia. We occupy the segment of the market which is convenient for us and provide quality services to our clients.

LLP Targin: The fields in the regions where we operate, as generally in Russia, are conventional. The need to drill extended-reach wells will only grow with time. It is economically feasible in the regions with developed infrastructure as well as in the regions where construction of well pads is an issue due to environmental conditions. This being said, demand for wells with horizontal completions is expected to grow, as it is an advanced way to achieve high production rates and increased recoverability of reserves. However, in my opinion, increasing the length of horizontal completions, particularly in old fields, is rather a controversial issue.

Currently, most of the production and side-tracked wells constructed by LLP Targin Bureniye (Targin Drilling) both in Bashkorstan and Western Siberia are directional, 30% of them (and in the Republic of Bashkorstan – 90%) are horizontal completions. Drilling is performed on the basis of sharing services by different contractors.

PNG Drilling Company: It appears logical to divide this question into serveral sub-questions. Horizontal and extended reach wells drilling are methods of field development and reservoir management which in part touch economic aspects of capital investments in developing comercial hydrocarbon reserves. However, the sanctions belong, I would say, to a different set of phenomena, political ones, in my opinion. These phenomena could not affect decisions of a geologist developing a field. In other words, if an operator needs horizontal or extended reach wells to manage a reservoir and produce from it, for a development geologist, the existence of sanctions is not particularly important. An operator would require these particular wells. However, the availability of such services is a different issue. Fortunately for the local industry such technologies and services are available even in the presence of sanctions, including technologies and services provided by the national oil service and drilling companies, including PNG Drilling Company.

ERIELL Group: The demand for horizontal drilling is constantly increasing due to the fact that the subsoil users have realized a simple rule – “the longer a horizontal section is, the cheaper the well construction costs are due to the reduced number of wells needed, as well as the the increased volume of production of the well, owing to the length of the increased reservoir contact area”.

2. Rig upgrades and availability has always been a regional hot topic. Does Russia have the rig size and horsepower to satisfy regional horizontal projects? What alternatives are there?

Halliburton: It is well known that Russia faces a major challenge because of the poor quality of the country’s rig fleet. In many cases, the existing rigs do not meet the requirements to drill horizontal wells with the complex profiles that customers now require. Most of the problems focus on the rig auxiliary equipment and the inability to add more advanced top drives, triplex mud pumps, and variable speed rotary tables that are required. The stresses applied to the drillstring downhole also increase with the complexity of the wellbore. In many cases, either the size or grade of the drillstring, required to drill efficiently, is not yet available.

The Design of Service (DOS) is the initial process Sperry Drilling uses to assess the well design and customer requirements. All required calculations are performed during the planning stage, and recommendations are forwarded to the customers. These can include modernization or replacement of certain rig elements, selection of the drillstring, and optimization of the well profile and wellbore placement. Moreover, Sperry Drilling can propose solutions to drill complex ERD or horizontal wells by factoring in the capability of the rig. An example of such a solution is the Geo-Pilot® rotary steerable systems (RSS) with a GXT power section, which allows rotating with lower top-drive RPM’s when drilling horizontal ERD wells.

LLP Targin: It is, indeed, a serious issue. It has arisen because, traditionally, rigs were manufactured in Yekaterinburg (Uralmash) and Volgograd (VZBT, Volgograd Drilling Equipment Plant). “Perestrojka” affected this industry, as well. The situation is particularly difficult in the heavy drilling rig manufacturing sector. There was a significant drop in manufacturing while the rigs which are available in the market are worn out and obsolete, with their end of service life of 25 years from their date of manufacture, which is now approaching. The way out of this situation is through partial refurbishment, involving the change of derrick and draw-works modules and skidding systems. This also generally results in a capacity increase of up to 250 – 270 tonnes. The above does not provide a solution to the problem of comprehensive renewal of the rig fleet. However, it would allow the equipment service life to be extended and meet the requirements of the projects for the construction of extended reach wells, as a result of the increased rig performance and size.

Apart from traditional manufacturers, such work is currently also performed by new enterprises: first of all, by LLP Generatzia, as well as LLP ASK and LLP OuSPK (Urals-Siberian Industrial Company). The alternative is the the acquisition of imported drilling rigs, primarily produced by Chinese manufacturers, who maintain low price levels, compared with their competitors, and offer acceptable quality.

PNG Drilling Company: Recently, investments in oil, gas and drilling machinery manufactured in Russia have been on the increase. We hope that this tendency will continue and grow. Currently, Russia produces drilling rigs of all types and capacities. Thus, in general, drilling rigs of all types and capacities are available in Russia for drilling horizontal and extended reach wells. In my opinion, the issue is selection of a drilling contractor based on price and quality criteria.

ERIELL Group: The capabilities of Russian rig manufactures allows for the design and manufacture of all types of drilling rigs which satisfies the full demands of the regional drilling projects. However, when the subsoil user sets a task to drill deeper wells, the situation will change and Russian drilling companies will turn to foreign manufacturers.

3. From a downhole perspective what are the common challenges faced, in the regions, when drilling horizontal or extended reach wells?

Halliburton: Because of the complexity of horizontal well profiles, one of the problems the industry experiences is transferring weight to the bit while drilling when using a positive displacement motor (PDM). For horizontal ERD wells, “stick slip” becomes an issue, causing an inability to direct the well bore, which prevents further drilling. In this case, RSS’s are often the best solution. They deliver constant rotation and improved hole quality, which contributes to improved hole cleaning, allowing cuttings to be effectively transported to surface while drilling.

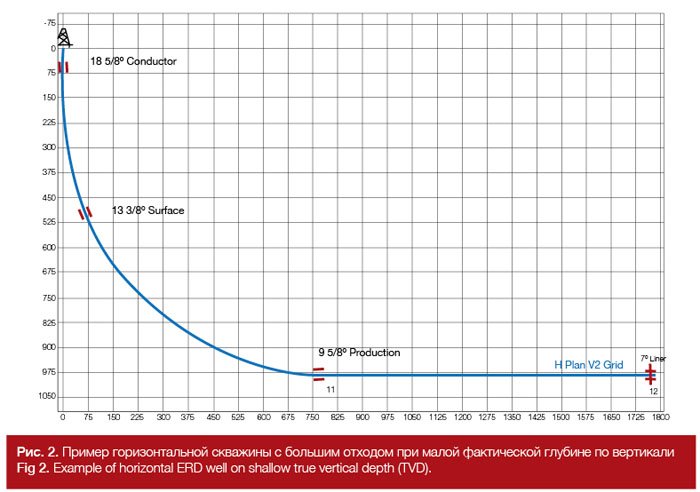

Another issue customers experience when drilling horizontal wells is thin pay zones (in some cases, 0.5 to 1 m) (Fig. 2). The solution for this is to integrate logging-while-drilling (LWD) tools into the bottomhole assembly (BHA)—resistivity, density, thermal porosity, acoustic measurements, bed bounding—and deploy real-time geosteering services, of which Sperry Drilling is a leader in the industry. If wellbore stability is also an issue, then geomechanics services can be integrated. These solutions help keep the drillstring in the pay zone, correct the well path in real-time, and evaluate reservoir and geomechanical properties.

LLP Targin: The biggest problems that we face are loss of circulation, ensuring the stability of the wellbore and ensuring incident free drilling on reservoirs with low pressures. The second issue is a lack of design solutions that ensure good well construction. The second issue is the insufficient development of the design solutions which would ensure a good standard of deviation in the wells construction. This is caused both by insufficent experience in designing similar operations and the wish to reduce construction costs to a minimum.

PNG Drilling Company: The companies I represent – PNG Drilling Company and PNG Service Company – are well drilling and cementing contractors respectively. MWD is an additional service provided by an external contractor. As a Client (main contractor on some turnkey well construction projects) we, unfortunately, sometimes have to bear geological, engineering and technical risks associated with wells, which in theory, should be a subsoil user’s risk. In this respect the problems could be numerous: reliability of MWD systems and downhole drilling motors, risks of well integrity loss in horizontal sections during a catastrophic loss of circulation and kicks. It is particularly a problem when the latter were not included in the design, in advance, and there is no equipment or materials on a drilling site for managing such complications. It is virtually imposible to describe all potential difficulties. One should prepare meticulously before constructing any well and particularly horizontal and extended reach wells – one should optimize well drilling by using relevant software, identify all posible risks and complications, estimate the budget for managing complications, etc. Unfortunatley, a client /subsoil user does not always have the required budget and the time necessary to perform detailed preparation for well construction.

ERIELL Group: Some of the problems include disastrous lost circulation, high torques of the drilling string and fluid kicks.

4. Russia has significant brownfield reserves. Has there been an increase in sidetrack drilling within these fields? If so, what have been the results?

Halliburton: Sidetracking is an important process to help extend the life of mature fields. Brownfields can bypass pay (not identified when originally drilled) or known pay zones at different depths that were not the main target at the time the wells were drilled.

Also, operators can sidetrack from an existing wellbore and add a lateral well for more reservoir exposure.

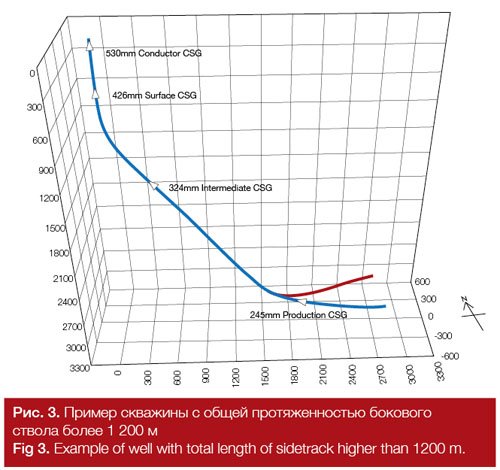

Drilling a sidetrack can reduce costs associated with the top side (TS) construction of wellheads and pipelines and “subsurface” casing construction, as these are already in place. Sperry Drilling has extensive experience in drilling sidetracks of different diameters and lengths (over 1200m) (Fig. 3). Drilling these wells addresses most customer issues. More complex wells require an individual approach and a wide range of specialists, such as optimization engineers (ADT® drilling optimization service), who are responsible for monitoring and optimization processes in real-time.

LLP Targin: In Russia the majority of fields are probably near-depleted. Side-tracking is a good solution which allows drilling of in-fill wells, including the core samples, when re-interpreting the fields data. Moreover, the cost of side-tracking is generally one third, or half that of a new well a half of that of new well construction. It is also possible to use the existing surface facilities and with sufficient scrutiny of previously exploited deposits, success rates can reach 50%. It is hardly surprising that the demand for side-tracking increases annually, but also so does the complexity of the challenges to be achieved. If, previously, it was necessary to perform a simple re-drilling of a well, drilling a new hole with a new reservoir penetration point, currently the objective is to drill a new hole with horizontal completion which is often used for for multi stage hydro-fracking. Based on our practical experience, side-tracking with horizontal completion in the Republic of Bashkorstan resulted in an increase in the production rates.

PNG Drilling Company: Yes, side-tracking in Russia is on the rise, as can be seen from the tender statistics. This could be seen from tender statistics. As a drilling contractor we do not receive any geological data from the operators regarding efficiency of individual side-tracks due to confidentiality of geological data. As far as I can judge, there is an economic effect which is considerably higher than that of drilling a new well.

ERIELL Group: With the low oil price and the resulting reduction in the production well construction programs, by the subsoil users, led to a dramatic increase in the demand for sidetracking due to its low cost as compared to production drilling.

5. What specific problems often occur within brownfield sidetracking operations in Russia? How can these be overcome and solved before they rise?

Halliburton: A major challenge with sidetracking is the complex well profile designs with high doglegs of both build and turn. Unfortunately, not all Russian oilfield service companies have the required expertise and technology. In many cases, customers require corrective actions to resolve issues originating from the initial attempt, which affects viability and costs.

Safety is a primary concern, and a key objective is to help ensure safe drilling and minimize collision risks. To achieve this, advanced measurement-while-drilling (MWD) systems are used with high measurement accuracy and dedicated survey management software to quantify and correct for any external magnetic effects.

C.A.T.oil AG: The group of companies, C.A.T. oil AG, provides a wide range of oilfield services (side-tracking, well drilling, hydro-fracking as well as well workover, isolation and cementing). Our experience of working on various assignments shows that side-tracking is both the most technologically advanced and hazardous operation in oilfield services.

Side-tracking in a field which is being actively developed and is inevitably associated with serious difficulties. There is a high probability of technogenic effects caused by the drilling targets as the result of active formation development in the areas where sidetracking is performed in old stock wells (formation pressure maintenance, production, intense wellbore intervention, etc.). This leads to the highest degree of uncertainty in relation to the information on combined pressure curves which creates such complications as collapse, gas, oil and water kicks, differential sticking, etc. Side-tracking with horizontal completion in near-depleted fields under production is associated with high accident risk during the operations.

Currently KATOBNEFT, a subsidiary of C.A.T. oil AG divisions confidently performs side-tracking in the wells of various clients in Shirotnoye Priobye (Latitude Priob), Western Siberia Oil Basin. More than 1000 wells have been drilled. The efficient performance of the Geological, Design and Technology Departments combined with highly technically, and technologically, equipped drilling teams enable us to perform work in abnormal operating conditions when drilling lateral holes with horizontal sections in near-depleted fields.

LLP Targin: The most serious risks are associated with discrepancies between the design and the actual well data, both in respect of trajectory, physical casing condition and presence of annulus equipment. This means that before commencing actual side-tracking it is very important to perform comprehensive preparatory work: construction of an updated profile using a gyroscopic inclinometer and quality control of casing and technical condition of the production string. After this, dangers will be lurking during the actual side-tracking. These are generally due to low bottomhole pressure and technical issues of operating within a limited diameter which do not allow for the use of the majority of technical devices which ensure drilling safety.

Thus, in order to resolve side-tracking challenges successfully it is necessary to consider sidetracking safety issues. This should be done at the stage when the technical condition of the current well hole is assessed, the drilling programme is approved and issues of incident-free completion have been resolved, including casing running and cementing, where necessary.

PNG Drilling Company: I believe many will agree with me that the most essential things in any drilling operation, including side-tracking, the reliability of equipment, the profesional competence of the engineers and operating personnel, and the use of trusted external service contractors. We do not have any statistics which would compare complications when side-tracking in old and new wells. Undoubtedly, in the old wells one should take into account the additional ssociated risks with the casing condition, after 15-20 years of service, well design, the diameters of the intermediate casings through which side-tracking windows are cut, etc. These risks should be reduced to a minimum by detailed preliminary development of the side-track design.

ERIELL Group: The main problem is the alternation of low- and normal-pressure formations which, in its turn, leads to the risks of lost circulation and fluid kicks. Complications are usually prevented by the correct selection ofdrilling muds to isolate such zones and by the control of drilling fluid density.

6. Operators are working hard to reduce their CAPEX spending. How can an operator minimize their conventional horizontal drilling and sidetracking costs?

Halliburton: Presently, many operators realize that lower drilling costs can be achieved not only through reducing costs at every stage but also by applying more expensive and efficient technology. For example, LWD services can eliminate the need for wireline logging, and RSS, such as Geo-Pilot systems, can improve the rate of penetration (ROP) and reduce the number of wiper trips required. Drilling optimization services control downhole shocks and vibrations, which results in reduced non-productive time (NPT). Geosteering services help deliver precise wellbore placement, thus placing the wellbore in the sweet spot of the desired reservoir and thereby helping to maximize production and recovery rates.

Multilateral wells can also reduce capital expenditures (CAPEX) because they allow for more horizontal sidetracks to be drilled from the same wellhead/pad, which results in a larger drainage area and higher oil production rate.

C.A.T.oil AG: Talking of reducing drilling costs, there are two approaches. The first approach – changing drilling costs by reducing the cost of services provided by contractors, as well as the material suppliers’ costs. The second way, which, in my opinion, is the most appropriate one, is to improve the well construction time, both while side-tracking and drilling. The main cost component is the drilling rig rental and costs for the services required during drilling. We are aware of examples when a client aimed his efforts at attracting high-standard contractors, who were not at all cheap, and established effective engineering services. As a result, he significantly reduced well construction time. If we are talking about the necessary measures during a crisis and low oil prices, these measures should be more radical. For example, it is necessary, as far as posible, to give up all geophysical and other investigations, simplify geo-navigation to the maximum and reduce drilling of pilot holes in horizontal wells.

LLP Targin: It’s very simple: it is necessary to critically review the well construction experience and to use all the available geological data including core samples and the current formation pressure data to design a well pattern. As for the actual operations, one should use up-to-date equipment and technological solutions which would allow for the reduction of well construction time and ensure that the wells are brought into production on time.

PNG Drilling Company: As they say, “this is a good question”. I am deeply convinced that the key to reducing costs should be efficiency. This means that at any stage of well construction design and planning one should give the utmost consideration is given to the specific project, equipment to be used, special additional services which could result in increased total daily drilling rates. Eventually, all this should enable shorter well construction time. The saving will be reflected in the absolute price of the well and not in the low daily drilling rate which is often viewed out of context, i.e. without taking account of the services, total well construction time and its final cost. Unfortunately, it does not always happen in a free market. The tenders are held mainly by comparing daily drilling rates of drilling contractors, disregarding advantages of drilling rigs of a contractor who, at first glance, is more expensive, and the contractor’s potential to reduce the well construction period and produce additional oil.

ERIELL Group: An operator may hold a separate tender procedure for each type of service and engage the drilling contractors on a daily rate basis thus ensuring manual control of the project.

7. Optimal rates of penetrations, a high wellbore quality, as well as hitting the payzone are key requirements on all horizontal and sidetracking operations. What are the best practises an operator can employ to ensure horizontal and sidetrack success?

Halliburton: The Geo-Pilot RSS point-the-bit technology provides the proven speed and hole quality benefits required. Equipped with ABG™ at-bit gamma and ABI™ at-bit inclination sensor modules, this system can be used to drill horizontal wells in the desired thin pay zone. The Geo-Span® downlink communication system is another solution for helping to reduce drilling days. This system is capable of transmitting commands to BHA tools (RSS, MWD, LWD) while drilling at a constant ROP. Commands transmitted by the system allow for more precise well placement and updating of real-time logging data in response to varying geological data.

Selecting the proper bit and PDM combination is also an important aspect of horizontal drilling optimization because drilling conditions in different Russian regions can vary substantially. Experts from Sperry Drilling in collaboration with bit design teams select the best PDM in terms of RPM and output torque to identify bits for specific geologies. The GeoForce® enhanced performance mud motor, with its even-walled powered section, increases the ROP by 30 to 50% compared to conventional PDMs.

C.A.T.oil AG:

Talking about drilling, our clients perform most of their work on the basis that the services are shared by different contractors.. This enables a client to be in full control of well construction, to accumulate experience and applying the most advanced technologies. Various geological environments in different operators’ fields require the use of relevant technologies. There are many of these technologies in the current market – drilling using rotary steerable systems, underbalance drilling, casing drilling and use of various drilling mud systems. The main and important factor is the cost which should be justified. With the Rouble loosing its value and oil prices dropping the operators can not justify the use of expensive technologies.

LLP Targin: There is a host of options here. All of which depend on the objectives which have been set. I believe that, apart from selection of an optimum well trajectory, the most important thing is real-time drilling monitoring and performing the necessary trajectory adjustments taking into account the actual condition of the penetrated section.

PNG Drilling Company: To achieve drilling efficiency an operator should be aware of the technological capabilities and advantages of modern drilling rigs and should be able to use them in specific geological and technical conditions in his license area. An operator should employ advanced drilling rigs which, unfortunately, we do not have many of in the country. I am referring to modern mobile drilling rigs capable of producing controlled downward pressure on a drilling bit without changing the downhole assembly (pull down system); mobile drilling rigs capable of producing hydraulic pressure on the casing shoe when the casing is run in inclined horizontal sections of a well; drilling rigs which enable running-in casings with flushing and casing rotation using standard equipment at any stage of casing running without the need for additional operations to install subs, flushing packers, etc. Advanced modern technologies and services using continuous mud circulation without breaks for connections, using managed pressure drilling system, etc., are also effective.

ERIELL Group: Essentially, it is required to apply a combination of complex technologies which often include:

• oil-base drilling fluids;

• rotary steerable systems together with logging while drilling;

• measurement-while-drilling systems with a hydraulic channel;

and other well-known technologies.

8. What are the common causes of NPT during horizontal and sidetracking operations? What is being done to minimize NPT on these projects?

Halliburton: The most common causes of NPT are rig downtime resulting from equipment failures and breakdowns. Another important reason is the so-called “hidden NPT,” which is often neglected. Hidden NPT includes non-optimal crew performance, inefficient use of equipment, and poor cement jobs, which do not provide a sufficiently strong kickoff point for the BHA. These are generally not considered NPT but can be eliminated to help improve efficiency. According to a survey conducted, hidden NPT can account for 20% of the total well construction time.

Also, to help minimize NPT, experts perform analysis and provide recommendations to customers. The focus is on controlling downhole shocks and vibrations so that the energy directed into the bit/BHA is used to drill new formations instead of being lost to harmful vibrations. Geomechanics and geosteering services can help minimize NPT risks related to geological transitions. Bit/BHA damage can also be caused by shock loading, which occurs as a result of poor surface equipment calibration of the rig equipment.

Sperry Drilling continually works to improve systems to handle current and new challenges in each area of rigsite operations.

C.A.T.oil AG: The most significant costs incurred by all contractors and operators due to NPT are the result of accidents and geological complications. Consequences of downhole incidents are loss of expensive equipment in a well and repeated drilling. Incident causes vary: a human error, equipment failure or difficult geological environment. Measures to prevent NPT start at a well design stage. It is essential to obtain information from the client required for design of downhole operations and perform an efficient risk assessment before commencing drilling or side-tracking. At this stage a combined engineering effort by the contractor and the client is important, and the rule “The client is always right” does not apply in this case. One more important issue is the shortage of qualified personnel in the labour market. We could have a good project and high-end equipment, however, based on all drilling contractors’ experience, a proportion of accidents were due to a human error. This is a global problem and the contractors would not be able to resolve it by themselves. Government-led programmes are required but at the moment we are making our own effort to improve skills and expertise.

LLP Targin: When the project management is efficient and the effects of such factors as the actual condition of drilling equipment, tools and personnel qualifications are excluded, the main problems could only be those related to the discrepancy between the design data and the actual penetrated section. These problems result in stoppages associated with the need to re-evaluate the geological information, develop solutions for the profile change and, in the worst case scenario, re-drill the hole using a new trajectory.

Thus, we come back to the issue of carefully studying the design documentation for the construction of an additional (side-track) hole at the design stage.

PNG Drilling Company: In my opinion, NPT is mainly associated with drilling equipment failure, the second factor being engineering and geological complications in a wellhole, loss of circulation or kicks.

ERIELL Group: Complications and incidents in the course of well drilling can result from the incorrect information specified in the design documentation.

9. What tools or services are you running in Russia for horizontal and sidetracking projects? Do you tailor your solutions the different formations and rock types found across the regions?

Halliburton: The Sperry Drilling business unit employs the entire range of directional drilling equipment for horizontal drilling and sidetracking in Russia, including PDM, RSS, and LWD tools, along with ADT and geosteering services.

As mentioned, drilling environments in different parts of Russia can vary substantially; therefore, each project is unique in the current context. As such, for each case, it is essential to determine the best bit + PDM or bit + RSS combination, find the most-suitable LWD sensors, and draw on lessons learned from previous projects, including those involving experts in seismic analysis. For example, based on experience, PDMs with a fixed bend angle are used. PDMs that are sent to the rig are ready-to-use, which saves significant time during BHA makeup. As this type of PDM can be used in more aggressive drilling environments, the ROP increases considerably, reducing well construction time.

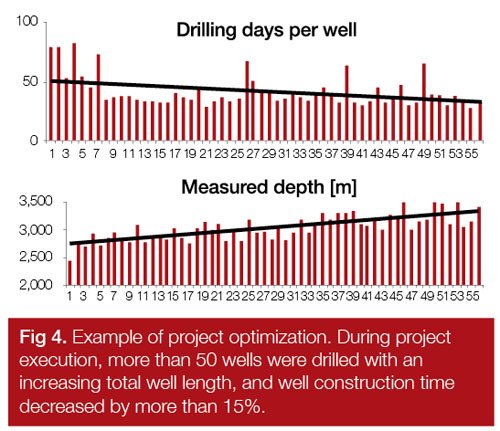

One example of successful adaptation and optimization of well construction performance is the Sredne-Botuobinskoye field (Fig. 4), where the drilling time was reduced substantially.

C.A.T.oil AG: To perform drilling and side-tracking projects we use mobile drilling rigs. Thus, the technical design specifications for the rigs to operate in the Far North environment were developed jointly with National Oilwell Varco. The rigs are designed to drill wells up to 4000 m and are equipped with top drives. Such high-end equipment enables us to implement complex technological tasks set by the clients. High mobility of drilling rigs turned out to have a competitive advantage over heavy stationary rigs. In drilling we operate on a daily rate basis. Therefore, using services and employing technologies is a client’s prerogative. On our behalf we guarantee professionalism of our drilling teams and high quality drilling equipment.

Side-tracking is generally performed on a turnkey basis where we have an opportunity to design a well and offer the use of various technologies to our clients. Many technologies offered to clients have subsequently become standard and compulsory for other contractors. Our company has successfully mastered, and is now implementing, two-stage liner deployment and use of various types of eccentric shoes. We also successfully used light-alloy drill pipe for side-tracking for the first time.

LLP Targin: Depending on the defined objectives we use all of the best practices and technical and technological solutions which are briefly described below:

• use of different design slips with a set of cutters which allow cutting a window in one run with preliminary orientation at a pre-determined azimuth;

• using MWD with a hydraulic communication channel and additional modules of gamma ray and resistivity logging transmitters;

• use of special tools for multi-hole completions;

• use of various special tools (heavyweight drill pipes, reamers, oscillators, etc.);

• use of various liner hangers enabling the casing to be run with or without cementing including installation of filters or special ports for multi-stage hydro- fracking and many other solutions.

PNG Drilling Company: We are convinced that it is possible to drill horizontal wells and side-tracks more quickly and efficiently if a contractor has the most advanced drilling rig and cement units fleet. Our companies, BK PNG and SK PNG have the most advanced drilling and cementing equipment. Based on the “youth” of the main equipment, BK PNG and SK PNG are undoubtely the leaders in the Russian market. Our drilling rigs and cementing units are no older that 1-2 years. We have drilling rigs which are unique in Russia, for example a mobile drilling rig Viking 6000 WEI D 340-32 produced by an Italian company WEI (WEI Srl, Fiorenzuola D’Arda). This rig with capacity of 340 metric tonnes can be transported by only two semi-trailers! All our mobile drilling rigs have the same equipment and possibilities as described above as a standard, i.e.: a “pull down” system, an “over top drive” system, use of overshot instead of conventional elevators for runnings casing, tripping, etc.

ERIELL Group: Individual well construction programs have been implemented with the use of rotary steerable systems, Vortex, LWD and biopolymer muds. Besides, optimal drilling performance has been ensured through pre-drilling geomechanical analysis, on-line technology planning, “drilling on paper” with the elimination of problems associated with kicks, wellbore instability and lost circulation. ERIELL Group has been successfully applying the following technologies:

• drilling in the most complicated drilling and geological conditions: with hydrogen-sulfide and carbon dioxide aggression, underbalanced drilling, drilling through salt-anhydrite formations, in salt creep areas, under abnormally high and abnormally low formation pressures, in areas with partial, full and disastrous lost circulation;

• the segregation of productive formations in complicated geological sections;

• the application of horizontal well casing methods preserving reservoir properties;

• the application of clayless, biopolymer, polymer-salt, polysaccharide muds and also oil-base muds;

The adaptation of technologies to different drilling and geological conditions is mandatory.

10. Can you outline a recent horizontal success you have had in Russia? (please explain the systems used)

Halliburton: Sperry Drilling has numerous success stories. The most impressive include the following:

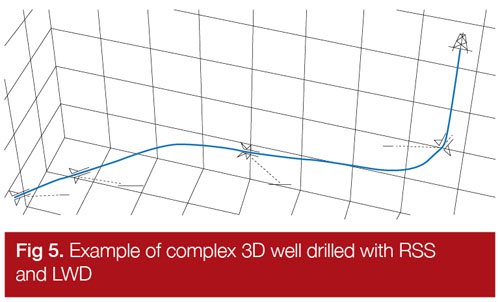

• West Siberia—3D profile drilling with horizontal sections over 1000 m long using RSS, LWD, and geosteering tools in real-time. For this project, well construction time was reduced by five days from the estimated drilling time (Fig. 5).

• West Siberia—Drilling ERD wells using RSS, LWD tools, and geomechanics and geosteering services. Well construction time was reduced by 12 days per well. No NPT was observed.

• Offshore Sakhalin Island—An offshore well drilled using RSS, advanced LWD tools, and geomechanics and geosteering services in the 311- and 215.9-mm sections. For the first time in the project’s history, the well was successfully drilled to total depth (TD).

• Yamal—Drilling multilateral horizontal wells using advanced LWD tools. It was possible to drill up to four horizontal sidetracks in one trip without pulling the BHA out of hole.

• East Siberia—Drilling a horizontal well using RSS and advanced LWD tools in production and liner sections. It was possible to drill a horizontal interval with ROPs exceeding 100 m/h.

C.A.T.oil AG: Mobile drilling rigs used for by our subsidiary CAT Oil-Drilling are limited to 200 tonne capacity. Therefore, we can’t boast of drilling record horizontal wells. However, we drilled wells in the Yamal-Nenets National District with a horizontal section of 700 m and the total depth of 4500 m. We were also involved in multi-hole drilling of horizontal wells in this area. The Schlumberger Rotary Steerable System was used in most of the wells. 200 tonne capacity rigs operate at their maximum capacity when drilling such wells, consequently, we stopped working on projects of

this kind.

We focus on the quality of services we provide and improving well construction time. We have experience of reducing identical well construction time from 90 to 45 days. Such results were achieved by careful selection of drilling equipment, efficient project management and good partnership with the client.

LLP Targin: As an example of successful, horizontal hole drilling by our company we can quote the application of advanced technologies using drilling oscillators. This enabled us to increase drilling bit loads and ROP in the horizontal sections by a factor of 3 or more (from 4 m/hr to 14 m/hr), for example, in wells 159 and 157 in the Khasanovskoye Field.

• When drilling wells in the Devonian, where drilling conditions are difficult and high-permeability low pressure formations alternate with claystone formations prone to caving and collapse, we installed a profile packer (OLKS-216) in an unstable horizon (the Kynovskiy). The well was drilled without any accidents.

• When drilling horizontal section of the side track in the Malo-Balyskoye Field we managed to increase ROP by a factor of 3 or more (from 2.5 m/hr to 8 m/hr) by using the bottomhole assembly (drill bit, motor, MWD system and a drilling jar system) provided by one service contractor.

• Use of special technologies and technical equipment (a slip for side-tracking of the second hole in an uncased well) enabled us to implement the project for construction of multi-hole horizontal wells with a partial access to the upper hole in the Voyadinskoy Field wells.

PNG Drilling Company: To provide a brief description of work successfully performed by PNG Drilling Company and PNG Service Company would not be an easy task. It could become a subject for a separate article. I can only mention that we are working for LukOIL and Rosneft. For example, we completed a 2014 well drilling programme for RITEC (Russian Innovation Fuel and Energy Company, LukOIL Group) in Samara Oblast 106 days before schedule thus providing additional production for our respected client for almost 1/3 of a year. We are also trying to gain a reputation of the most preferred drilling contractor for Rosneft under the current 3-year contract.

ERIELL Group: ERIELL Group was the first drilling contractor in the world to successfully drill horizontal wells in the Achimov deposits with horizontal section lengths over 1000 m. The Company was selected as a general contractor for the construction of several horizontal wells in the Achimov deposits. The drilling rig BU-5000 (URALMASH), with a TESCO top drive system, was used for the construction work. The high priority for ERIELL is the quality of the work which we conduct and the observance of industrial safety standards and environmental regulations of the Russian Federation. To achieve this target, the Group engages a team of professionals with many years’ experience of work both in Russian and on international projects including specialists from the leading service companies.

The difficulty of the well construction process stems from entering a horizon with abnormally high formation pressure and constructing a long horizontal section (over 1000m). The profile of this well is unique for wells constructed in the Yamal-Nenets Autonomous District. To monitor the parameters of the target trajectory, it was necessary to use equipment from the world’s leading suppliers which would ensuring realtime geological steering and also provide an assessment of the fluid composition and the reservoir properties.

A sub-horizontal well within the Achimov deposits, with horizontal section of 1048m, was constructed in 47 days. This well was delivered significantly ahead of schedule, which hadn’t been previously achieved by any company. This is a great victory and opens new possibilities and perspectives in the future.

Dmitry Gubernatorov – Halliburton

Dmitry Gubernatorov is working as Senior Country Manager at Sperry Drilling in Halliburton company since 2013. Dmitry graduated Tomsk Polytechnic University with diploma “Oil & Gas wells drilling” and also he completed Halliburton President’s Leadership Excellence program in Texas A&M University in 2014 . As drilling engineer he started his career in 2000 working for drilling Contractor and worked his way up to Country Manager at Sperry Drilling.

Vladimir Yevstigneev – C.A.T.oil AG

Vladimir Yevstigneev heads the Drilling Division of C.A.T.oil AG. The company provides drilling and side-tracking services in Russia using 26 side-tracking and 15 drilling teams. In 1986 Mr. Yevstigneev graduated from Goubkin Moscow Institute of Petrochemical and Gas Industry with a degree in Oil and Gas Well Drilling. He has 29 years of practical experience in field exploration and development, of which 12 years he worked in various positions in Schlumberger. He has practical experience in deep hole drilling, side-tracking and well workover in Russia, including the Volga region, Western Siberia and the Arctic coast in Arkhangelsk Oblast.

Yuri Nikolaevich Sergeev – LLP Targin

Head of Drilling Department, LLP Targin

Born in 1958 in Dobryanka, Perm Region

1976 – 1981 – studied at the Mining Faculty of Perm Polytechnical Institute, qualified as a Mining Geological Engineer

1981 – 1996 – Polaznenskoye Drilling Department of PermNeft, career progressed from a Drilling Section Geologist to a Drilling Section Manager

1996 – 2002 – Principal Engineer, Polaznenskaya Regional Geological Office, CJSC LUK-Oil Burenie Perm

2002 – 2007 – Director, CJSC Severgeoldobycha (Naryan-Mar), subsequently Director of the Naryan-Mar Branch of LLP Bourovaja Kompaniya Evrazia (Eurasia Drilling Company)

2007-2008 – Design Office Head, LLP Neftservisholding (Perm)

2009 – 2011 – Head of Well Construction Division, initially in LLP Gazpromnfet-Vostok (Tomsk), subsequently in LLP Gazpromneft-Orenburg

As of 2012 – Head of Drilling Department in LLP Targin (previously known as LLP Bashneft-Servisnye Aktivy)

Zamir Abdullaev – PNG Drilling Company

General Director – PNG Drilling Company

Education: Institute of Defense Ministry of the USSR, Lawyer, 1986 (diploma with honours)

Institute of Defense Ministry of the USSR, Post Graduate, Ph. D. (Law) 1992.

Moscow International Business School, Degree in “International Oil and Gaz Business’,1993.

Ridgewood University, U.K., MBA in Oil and Gas Management, 2009.

Since 1992 was involved in oil trading business in Rosnefteimpex Co. of Rosneft JSC; Oil and Gas E. & P. business (USA-Russian private independent oil upstream company “Goloil”); Oil & Gas drilling & cementing wells business ( PNG Drilling Company).

Since 2008: CEO of PNG Drilling Co. Ltd. ( drilling and work-over services)

Awards: 2003 ZAO Goloil ( oil & gas producing company where Mr. Zamir Abdullaev was a Chairman of the Board of Directors) has been recognized as the most efficient enterprise in West Siberia of Russia with oil annual production up to 1 mln t.

2003 Gratitude of the Ministry of Energy of the Russian Federation.

2007 Certificate of merits by the Governor of the Krasnodar Region of Russia for successful development of oil and gas projects.

2013 Diploma of the Ministry of Energy of the Russian Federation for the substantial personal contribution to the progress of fuel and energy complex of Russia, for the longstanding conscientious work in the Oil& Gas Industry.

Ruslan Safarkhanov – ERIELL Group

For 15 years, Ruslan Safarkhanov rose through the ranks from assistant driller to Drilling Department Director; he organized numerous drilling projects from the initial stage and ensured effective control of the production technology and high marginality in these projects. Organization and management of production and engineering services at such large-scale projects as well drilling at Bovanenkovskoye (Gazprom JSC), Urengoyskoye (Novatek JSC) and Yuzhno-Tambeyskoye (Novatek JSC) fields can be regarded as a good example.