Technology Roundtable: Wellbore Cementing

1. How do you measure and calculate the optimum properties for the cement/slurry which will be pumped down hole?

Weatherford: Cement slurry design is based on the well data, such as bottom hole circulating temperature (BHCT), bottom hole static temperature (BHST), pore pressure and fracture gradient. Challenges faced by well operators include open hole instability, potential loss zones, water-bearing intervals and gas/oil bearing reservoirs which also have to be considered during cement design. We are able to design optimal recipes of cement and spacer based on all data above together with experience gained in specific regions or areas. We have labs with modern equipment certified by ISO 10426 and ANSI/API10 Standards for full cycle laboratory testing of cement and cement slurries. The tests include rheology test, thickening time test, fluid loss test, gel strength analysis, compatibility test, compressive strength test and special tests for flexible, expandable, self-healing and gas tight cement systems.

Schlumberger: It all starts with the proper planning; placing the cement in the annular is only the final step in a process that begins even before the well has been drilled-out. Once the required properties of the slurry and the set cement properties are establish. Computer software are utilized to simulate the job execution and the cement performance long term after its placement.

The next step is to replicate the designed properties in the laboratory out of representative samples of the designed components, including the selected additives used to modify the cement behavior; the design is fine-tuned to optimize thickening time, viscosity, rheology, stability, fluid loss control, free fluid, etc. Each one if these properties are independently measure with laboratory equipment specifically designed for the purpose. The sample is also cured under simulated wellbore conditions and its properties are also measured.

Halliburton: There are two major perspectives on cement design. One is the slurry design, where the fluids are tailored to allow successful placement in the wellbore, effectively displacing the drilling fluid in place and avoiding either influx from the wellbore due to insufficient hydrostatic pressure or inducing losses due to excessive hydrostatic pressure. The second aspect is the design of the set cement to be able to withstand the loads during the lifecycle of the well without failure. Obviously the second aspect requires the successful placement of the cement slurry first.

To characterize a cement slurry, there are lab tests, which are standardized under the ISO-10426 and ANSI/API 10 series of standards and specifications, which are identical. These include tests for Thickening Time (the time a slurry remains pumpable under agitation), Rheology (the hydraulic flow behavior of the fluid), Fluid loss (how much fluid is lost if the slurry is filtrated against a porous medium under pressure), free fluid and sedimentation characterizing the stability of the slurry system and compressive strength development.

Portland cement being a natural product, the slurry properties can vary quite significantly from producer to producer and even from batch to batch in one cement kiln plant. That is why typically every cement slurry design is tested with the actual cement and chemicals to be used in the field to ensure suitable properties.

To characterize the mechanical performance of the cement, methods from rock mechanics are used in combination with stress analysis models, which translate the operational loads on the well into stresses actually experienced by the cement. The mechanical behavior of the cement is measured on cores exposed to uniaxial or triaxial stresses.

2. What are the critical wellbore properties which must be considered when designing a cement job?

Weatherford: All critical well factors and challenges should be considered before cementing to mitigate the risks and prepare a contingency plan in case of any deviations from the cementing program. Those challenges include caving, lost circulation and potentially oil/gas bearing zones, high bottomhole temperatures and mud density. Optimal cement thickening time depends on bottom hole static and circulating temperatures. Cement thickening time is critical to design, when there are rate limitations during cementing pumping due to high equivalent circulating density (ECD) or low fracture gradient of the well. Lost circulation materials (LCM) are successfully used in the cement slurry to prevent losses during cementing in potentially weak zones.

Schlumberger: The well conditions shall be assess from two main perspectives, the required properties of the liquid slurry that allows an effective and safety placement and the long-term performance of the

set cement.

It is important to understand the lithology of the formation across the open hole section to be cemented since it strongly impact the hole shape, stability of the wellbore walls, the presence of permeable zones, as well as over-pressured or depleted formations.

The cementing fluids are designed to replace the drilling fluid while maintaining the well control in terms of hydrostatic pressure, rheology, fluid loss, stability and to prevent potential flow of any formation fluids, including gas. Once the cement sets, it must withstand the stress generated due to the subsequent activities of putting the well on production mode like perforations, stimulation jobs and even during the life of the well.

Halliburton: The first consideration when designing a cement job needs to be what the cement job is supposed to achieve. This leads to understanding of what slurry properties will be required, and where the cement needs to be placed.

Cement slurry properties (rheology, Thickening Time, Compressive Strength) depend strongly on the temperature of the fluid. Therefore it is important to understand the temperature regime in the wellbore under static

conditions and while pumping into the well.

To understand the wellbore response (inflow or fracture), the lithological column identifying rock types and possible reservoir fluids and pore- and fracture pressure profiles, as well as the borehole and pipe geometry need to be known.

3. Why is the temperature differential between the Bottomhole circulating temperature (BHCT) and Bottomhole static temperature (BHST) such an important factor when managing cementing costs and well control?

Weatherford: Dynamic (cementing pumping) and static (compressive strength development) stages have to be considered during cementing design.

Bottomhole circulating temperature, or BHCT, is used for designing cement characterized by optimal thickening time, rheology, and fluid loss. All those parameters have to be controlled during cement pumping (dynamic stage).

Bottomhole static temperature, or BHST, is important for compressive strength development to prevent the cement from strength retrogression during whole well life in case of high temperatures. BHST is often used for cementing design of HT wells with long horizontal section because it increases through heating of cement slurry during cement pumping in the horizontal section characterized by one temperature gradient.

Temperature is one of the most critical well parameters which has to be considered for cementing design. It effects cement slurry thickening time and compressive strength development. Cementing design with improper temperature data is associated with major risks, such as loss of hole or well control. Cement can set before the placement is completed and in this case it may be left in the casing. Also, if cement setting time is too long, it can increase the risk of formation gas or fluid influx in the cement structure and lead to cross-flows in the annulus.

Schlumberger: Chemical additives are used to modify the time in which the cement sets and develop compressive strength. The setting time is modified to make it long enough that allows the adequate placement in the annular, but it also shall be shorten to enhance the develop compressive strength. The set cement must prevent any migration of unwanted formation fluids, provide support to the casing and allow resuming operations to drill out the subsequent section below.

The setting time design is based on the BHCT, This one is lower that the BHST due the constant circulation of fluids along the wellbore and other heat interchange processes between the formation and the fluids.

Temperature is extremely important when designing a cement job; if temperature is under-estimated, the cement could set earlier in the pipe creating major cost due to the time to drill it out and to repair the failed primary cement job. On the other hand, if temperature is over-estimated, the cement could take much longer than required time to set; formation fluids, including gas can migrate thru it and create a hazardous well control situation, not to mention the delay time to resume operations.

Halliburton: The circulating temperature is the temperature the cement slurry will be exposed to during its placement in the wellbore. It will determine how long the slurry will be pumpable, and also its rheology. However this circulating temperature is dependent on the pumping program and the heat exchange processes taking place in the wellbore.

After completing the cement job, the wellbore will recover its static temperature profile over a period of approx. 24-48 hrs. This temperature will determine how fast the cement will build strength and therefore how long the rig will have to wait before continuing drilling.

From a cost perspective, the slurry needs to be optimized to provide sufficient Thickening Time while minimizing chemicals- and slurry cost, while also minimizing the required wait-on-cement time to minimize the rig time taken up by the cement job. However these two parameters are interrelated.

While attempting these optimizations, it is important to keep in mind that the cost incurred by a failed cement job is by magnitudes higher than the cost for the cement job itself, given that rig downtime, lost wellbore sections and delayed or missed production can result.

4. What are the key strategies for testing a cement bond and what draw backs are there to these techniques?

Weatherford: Integrated approach should be used for cement quality determination. Effective mud displacement is the primary goal for good quality cementing job. It can be performed effectively by designing optimal rheology of spacer and cement slurries and optimal rate of cementing for achieving a turbulent flow regime in the annulus during cementing. Casing stand-off and centralization program also effect mud displacement efficiency and cementing quality. Expandable and flexible cement systems have been designed for better cement coverage and prevention of cement bond destruction during well life including the completion stage. All those methods are integrated into cementing design and simulation by the special software CemPRO+ which is able to determine mud displacement efficiency and annular cement coverage. Those methods are not perfect as they can’t factor in real well conditions during cementing, such as the size and form of caverns and actual stress on cement bond, in the course of well completion.

Schlumberger: The quality of the cement behind the casing can be evaluated in different forms, depending on the desired grade of certainty required, it includes positive and negative pressure test to confirm annular seal, playback software simulations can also provide decent information about the expected cement quality, but the most informative source is by far the cementing bond logs.

There are occasions in which the cement detach from the casing for different reasons and therefore the response on the cement bond logs cannot be properly evaluated, in some cases it is recommended to re-log the section while applying pressure in the casing in an attempt to close the possible micro-annulus existing between the casing and the cement sheath. This operation implies the pressure containing equipment is available at the wellhead while logging and the cost associated for this operation and extra rig time consumed.

Halliburton: The simplest test on cement after placement in the wellbore is some form of pressure test to see if the cement provides the required pressure isolation. These can either add pressure to the hydrostatic column by pumping on the wellbore (positive pressure- or integrity test) or reducing pressure by selectively reducing the hydrostatic pressure with lower fluid density (inflow test). These pressure tests will mimic the expected loads, but they will not provide much insight into the mechanism of any possible failure.

Another way is diagnosing the top of cement in the wellbore. The easiest method here is a mechanical tag with the drill string or slick- or wireline, but this requires access to the top of cement. Alternatively, this can be estimated by analyzing the pressure behavior recorded during the placement and deriving the hydrostatic pressure exerted by the cement column. Also the temperature increase caused by the cement hydration in the wellbore can be measured by wireline log, giving an indication of where cement is and where it is not.

A dedicated method to analyse cement bond across the wellbore is by means of cement bond wireline logging. There is a suite of sonic and ultra-sonic wireline tools available, which derive information about the material behind pipe in the wellbore from analyzing the behavior of a sonic or ultrasonic waveform that travels through the casing and behind the casing. The attenuation of the waveform and the measured impedance of the material behind the pipe allows the distinction between solid matter and fluids. Recent developments also use eltromagnetic waves, as well as statistical waveform analysis to refine the results. However all logging methods are not quantitative, and are also influenced by environmental factors such as pipe wall thickness.

5. How do you over come the challenge of uneven or irregular wellbores and ensure you have the correct annular spacing?

Weatherford: Drilling, mud and cementing services should participate in preparation for cementing. This includes additional reaming runs, conditioning of the well by circulation of specially designed mud before cementing job. Our product lines Cementing Products and Cementing Services ensure high quality casing centralization (stand-off) using special software and competent engineering service to select required centralizers and places for their installation depending on inclination and caliper logging data.

All requirements to centralizers are included into API 10D standard which sets centering index at 67%. Weatherford rates reach 80–90% depending on well design complexity.

Schlumberger: One of the most important aspects while designing a cement job is to achieve a proper mud removal for the cement to be able to fill the annular space uniformly. Therefore, the selection and amount of the proper centralizers, strategically installed along the casing and/or the interest areas where the hydraulic isolation is most required.

Once the casing is centralized to the best possible option, then it is up to the mud removal strategy, which is based in rheological and density properties combined with displacement rates to maintain friction pressure hierarchies between the fluid that is pushing and the one that is

being displaced.

Halliburton: Stand-off, which means how far the pipe is away from the open hole wall, is crucial, as eccentricity results in a preferred flow path along the wider side of the annulus, with in extremis, a gelled fluid channel remaining in place on the narrow side of the annulus. The result is that not the entire borehole is filled up with cement, and channels can remain, which allow fluid movement and leakage after cementing.

Typically, the pipe is kept in the center of the open hole by centralizers, which are installed on the pipe body and kept in place by stop collars. There are numerous models and designs available, but they fall into two basic categories. Rigid centralizers have a fixed outer diameter (OD), which is not dependent on the load imparted on it. However this OD has to be smaller than the gauge OD of the hole, as the centralizer would otherwise get stuck. This limits the maximum achievable stand-off, especially if the actual hole size is larger than the gauge due to wash-out or other hole stability issues. Bow-spring centralizers incorporate some sort of a spring blade, which can extend beyond the gauge hole size. The centralizer can still run through tighter spots by compressing the spring blade elements. However, the deflection depends on the load imparted, and is higher in deviated boreholes, where part or all of the pipe weight are supported by the centralizer.

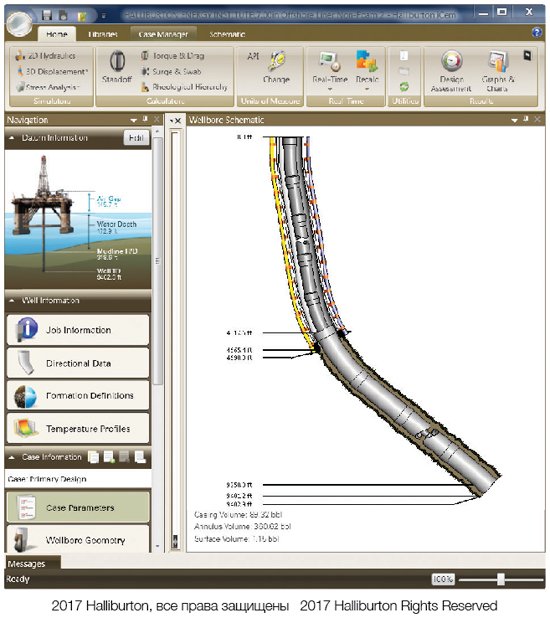

Modern cementing simulation packages such as Halliburton’s iCem® service can predict stand-off and the effectiveness of cement placement, considering the properties of the fluids to be used on the cement jobs, the performance characteristics and the spacing program of the centralizers and the actual borehole geometry as measured by an LWD- or dedicated wireline caliper. With these tools, the influence of the borehole can be assessed, and the centralizer selection and -spacing optimized to ensure that the cement can isolate the critical zones.

6. What systems and technologies do you have in place to help an operator achieve a cement job for the whole life of a well?

Weatherford: Cementing design depends on well data, regional challenges and stress on casing and cement bond during well life. Weatherford offers various technologies to meet customer’s requirements. The following technologies are in high demand at the moment:

• Gas tight slurry CemTite™ for gas wells prevents gas migration into the cement structure during the transition period when cement goes from liquid to solid state. These properties are ensured by the chemical which provides high fluid loss control and generates tight film on the cement slurry surface.

• Light-weight slurry such as CemLite™ is very common for wells with low fracture gradient and potential lost circulation zones.

• Flexible and expandable cement systems such as CemPly™ and CemPand™ which are getting increasingly popular for horizontal wells with multistage fracturing completion.

• Self-healing cement CemHeel™ designed for the wells with high formation pressure and high risk of annular fluid migration to the surface (such systems are used in the upper part of the annulus and include special additives which expand when the fluid goes through micro-annular cracks and block fluid migration

through cement).

High mud displacement efficiency is a very important factor. We offer an integrated approach consisting in high-quality design of spacer and cement slurries, development of centralization program and providing tools for casing rotation and reciprocation before and during cementing. We are able to determine and design mud displacement efficiency during casing rotation and reciprocation using special certified software CemPRO+ to determine flow regimes for efficient mud displacement and good cement bond.

Weatherford is the only service company that can apply integrated approach including Cementing Pumping Service, Cementing Hardware and equipment for

casing rotation and reciprocation to ensure high cementing quality.

Schlumberger: The oil industry had moved from easy access to more challenged environments in terms of depth, pressure, water depth, and formation properties. The most advanced cement systems include self-healing systems that can reestablish its integrity at the contact with hydrocarbons if ever lost for any reason. There are also flexible systems that withstand extreme well conditions during the life of the well including, perforation, stimulation jobs, changes in temperature and pressure during production and even up to a limited extend the natural events.

Halliburton: As already discussed, the placement of the cement slurry in the wellbore is only the first step. To ensure that the cement will maintain its function throughout the well lifecycle, the mechanical properties of the cement need to be designed to withstand the loads placed on it.

There are finite element software packages such as Halliburton’s WellLife™ software available, which can translate the planned operational loads during the different stages, such as commissioning pressure testing, completion of the well in lighter completion fluid, stimulation treatments etc. into the stresses experienced by the cement sheath. With these, the cement properties such as Young’s Modulus, Poisson’s ratio, compressive strength, tensile strength and expansion/shrinkage can be design to maintain competent isolation. With the identified property requirements, cement systems can be selected, tested and qualified in an iterative process to ensure a dependable barrier under the planned wellbore conditions.

The required resources for the characterization of cement mechanical properties are available in a network of Halliburton Technology Centers, which offer compression load frames and other specialized test apparatuses.

Reactive cement blends like Halliburton’s LifeCem™ cement can provide additional assurance, where wellbore conditions outside the planned envelope cause cement cracking. These systems react on contact with hydrocarbons to seal cracks and stop hydrocarbon flows to maintain the integrity of the cement sheath.

7. What specific solutions do you offer for high temperature and high pressure wells and wells in a corrosive environment?

Weatherford: The primary challenge in designing cement for HPHT wells is to solve the problem of cement bond strength at high temperatures and low fluid loss to prevent formation gas and fluids from getting into the cement structure. This is attained by using microsilica and silica flour with different particle size and concentration as well as plasticizers and fluid loss agents. We also offer special recipes of heavy cement slurries such as CemRock™ with the density of 2,3 g/cm3 for use in HPHT wells.

Schlumberger: Our portfolio includes system specifically designed to withstand high temperature environment for geothermal injection wells; we also offer systems with the ability to maintain its integrity when exposed to aggressive formation fluids like CO2 and H2S. These systems are based on engineered dry blends of proprietary products that are carefully arranged to exhibit superior properties compared to conventional cement.

Halliburton: Portland cement is susceptible to strength retrogression, caused by a change in phases at temperatures above approx. 110°C and to attack by wet CO2, the primary corrosion mechanism typically encountered in applications such as Carbon Capture and Storage and water injection. Sulfate attack might be another issue, but the oilfield-specific cement classifications cover this in a variety of specifications on sulfate resistance in the basic cement classes. Buying a High Sulfate Resistant (HSR) basis cement will prevent any issues on that side.

The thermal strength retrogression can be controlled by adding Silica components to the cement blend, which will prevent the formation of the destabilizing phase up to temperatures around 300°C. But the increasing Silica requirement will also affect the cement properties, so that alternative non-Portland systems might have to be considered.

Halliburton has two main products in the non-Portland high temperature field, Thermalock™ cement, a non-Portland cement, and Thermatek fluid, a temperature-activated sealant developed primarily for water shutoff and plugging operations.

Thermalock cement has the added benefit that it is not susceptible to CO2 attack and is therefore suitable for a corrosive environment.

8. With Russia drilling more directional wells, what challenges do highly deviated wells pose and how do you overcome these challenges?

Weatherford: As noted above, integrated approach to cementing of directional and horizontal wells is required. Customers often request high-quality cementing from cementing services providers when the quality of centralization is low. And for efficient cementing Weatherford always recommends to drilling and cementing contractors to properly condition the wellbore. Rotation before and during cementing also positively impacts the quality of cement bond, if it is impossible to ensure good centralization. Apart from that, we select cement slurry recipes with low rheological properties and optimal spacers to ensure cementing in narrow annular zones and highly deviated intervals without essential pressure increase due to cement friction during pumping.

Schlumberger: The mud removal and well-clean processes are among the biggest challenges for deviated wells. It is important to highlight the importance of the proper planning and the positive impact of working together with the operator to achieve the hydraulic isolation objective.

Drilling fluid selection, proper pipe centralization and the ability to rotate it, mud conditioning prior to the cement job, hole cleaning, correct selection and design of cementing fluids, ability to control friction pressure hierarchy, annular velocities, and the adequate temperature simulations are among the list to

closely control.

Halliburton: For cementing, higher deviations cause two kinds of problems. Firstly the installed centralizers in a near horizontal section will have to support almost the entire weight of the pipe, or the pipe will be pressed against the borehole wall. The resulting standoff might not be sufficient to ensure coverage of the entire annulus with cement. Rigid centralizers or high-strength bow spring centralizers will be required to achieve standoff for successful cement slurry placement. Pipe rotation, which will break gels on the narrow side of the annulus and distribute cement around the entire circumference is also an effective mitigation mechanism here. A collateral issue in this context is the ability to get a pipe string to the bottom of the hole without the support of the casing weight pulling down and increased drag friction on the pipe or centralizer touching the borehole wall. Low friction Protech™ composite centralizer blades, which are molded directly onto the pipe body, can help keepthe pipe body away from the wall and reduce friction factors. Good torque and drag modelling, available in Halliburton’s iCem™ and DecisionSpace™ software packages allow a prediction if a string can be run to depth successfully

or is likely to hang up prematurely.

The second challenge for cementing is that density hierarchy (heavier fluids displace lighter fluids upwards) does not work if the wellbore direction is no longer up or down, but horizontal. Fluid rheology design needs to receive additional care to ensure effective fluid displacement, where thicker fluids will displace thinner fluids along the direction of flow, irrespective of the direction of gravity.

9. With Russian fields operating over a wide area, in remote and harsh locations, this has a direct impact on cementing operation. How do you monitor and maintain the QA and QC of the slurry and equipment in harsh locations?

Weatherford: In remote areas with extremely low temperatures we use only dry additives for preparation of cement slurries and spacers. Weatherford has special pre- and post- operation procedures for vehicles in place. The vehicles shall be prepared for each trip and operation well in advance. It is highly important to use and properly control cement and spacer mixing liquids. The temperature of mixing liquids shall be close to the specific design temperatures for the cement and spacer to retain their properties in line with laboratory test results. We also provide recommendations on pressure testing of cementing lines before cementing using brines to prevent freezing.

Weatherford provides mobile labs designed for laboratory tests at remote fields. Heating units for the personnel at the rig sites in areas with extremely low temperatures are also available.

Schlumberger: Our organization has deployed and wide range of operating bases across the territory, we have a strong technical population present in every location. We are very proud of our high standard in regards of providing standardized training to our technical community; our engineers are engaged in a fixed step development process that includes technical schools in Russia and overseas.

The entire job process is also standardized to cover from planning to after execution. The quality control process are monitored to ensure the right performance of our additives, cement, equipment and as well as our personnel competence. We have built a technical network structure, which starts from the field locations and laboratories and grows to the district and county level until reaching a global community support, engaged in providing support and sharing knowledge across the globe.

Halliburton: Harsh locations pose a whole range of challenges for Cementing operations. Conventional cementing equipment might refuse to operate at low temperatures, water based fluids might freeze and possibly damage equipment, heat generated by hydrating cement could destabilize Permafrost soil near surface, and remote locations can make the mobilization of additional materials, spares and equipment seasonally impossible.

Halliburton is offering a range of ruggedized equipment like the Ruggedized Global Truck (RGT), which can operate in temperatures between -35°C and 45°C with self-contained mixing tanks and a winterized 8×8 heavy duty chassis.

To quality-control slurry designs in remote locations, Halliburton typically dispatches a self-sufficient service fleet to remote fields, which include a dedicated field laboratory, which can perform the operational testing for the fluids to be pumped on the location.

On the permafrost side, Halliburton can offer a variety of technologies, which can limit the heat release and ensure fill-up of unconsolidated and soft top holes.

Timur Oksyukovskiy

Since 2016 Timur Oksyukovskiy has been working for Weatherford as Sales Manager, Cementing Services. Previously he worked for a high-profile oil and gas service company as Cementing Project Coordinator and Technical Engineer in North America at Haynesville, Eagle Ford, Fayetteville and Marcellus fields for 5 years. He graduated from Gubkin Russian State University of oil and gas in 2010.

Pedro Florez

Schlumberger Technical Engineer for Russia and Central Asia.

With 20 years spent in the cementing business, Pedro has accumulated experience from several offshore locations in the Gulf of Mexico, Persian Gulf, Mediterranean Sea, Black Sea, Caspian Sea, Sea of Okhotsk and several land locations in North America, Mexico and Middle East.

Among others, he have been appointed in a variety of technical positions during his career including Deep-water Technical Manager in the Gulf of Mexico and Cementing Technical Instructor in the Schlumberger School in North America.

Zelimir Jekic

Zelimir Jekic is the Eurasia technology manager for Halliburton based in Russia since 2015. In total he has over 18 years of experience in cementing. He graduated in 1998 from Faculty of Mining and Geology, University of Belgrade in Serbia. After graduating he worked in NIS-Naftagas, Serbia in different roles and up to the position of team leader for cementing and acidizing department. In 2008 he joined Halliburton cementing team in Russia and led many critical operations including the University-1 well in Kara Sea for ExonMobil and Rosneft JV.