The First Cableless Telemetry in Russia for Wells Was Tested

This will eliminate the need for expensive cables and increase the reliability of oil production equipment.

For the first time in Russia, Tatneft tested a cable-free system for monitoring downhole parameters. It transmits information from the bottom of the well along the production string. Damage to an expensive downhole pressure gauge cable is a common problem when lowering equipment into a well.

The difficulty of measuring data from wells equipped with sucker rod pumps with production lifting along the production casing (USSHNEK) without the use of tubing is also noted. “Oil News” writes about this (Katerina MASHENTSEVA).

Using a standard solution in such wells is impossible, since the information transmission cable is fixed to the tubing. In this regard, in 2023, Tatneft began testing the Tri-Logic.DCS cableless monitoring system for downhole parameters.

The Elkhovneft NGDU well was chosen for testing the BSC. Wells were selected based on current data on the current bottom hole. In this case, the diameter of the production string had to be at least 146 mm. The permissible distance from the packer installation site to the bottom is at least 40 m. In this case, the well must be located in a cellular coverage area.

“Under field conditions, we needed to find out the viability of the two most important characteristics of the device,” explains Oleg CHATUROV, engineer for process control systems at the Tatneft-Dobycha JV. “This is the ability to transmit data via an electromagnetic communication channel through the casing and the quality of data transmission by this method.”

Tatneft specialists compared two complexes – cableless and cable – at certain intervals. The discrepancy was minimal, he notes.

The first attempts to introduce such technology were carried out back in 2005 and 2012 at Elkhovneft. But they were not successful, and the project was temporarily suspended. After some time, we managed to find a solution.

“During testing, we needed to confirm the performance of the battery in field conditions,” says Daniil ZAKURDAEV, a specialist at the Project Office of the Center for Technological Development of PJSC TATNEFT. According to him, the device should work for three years.

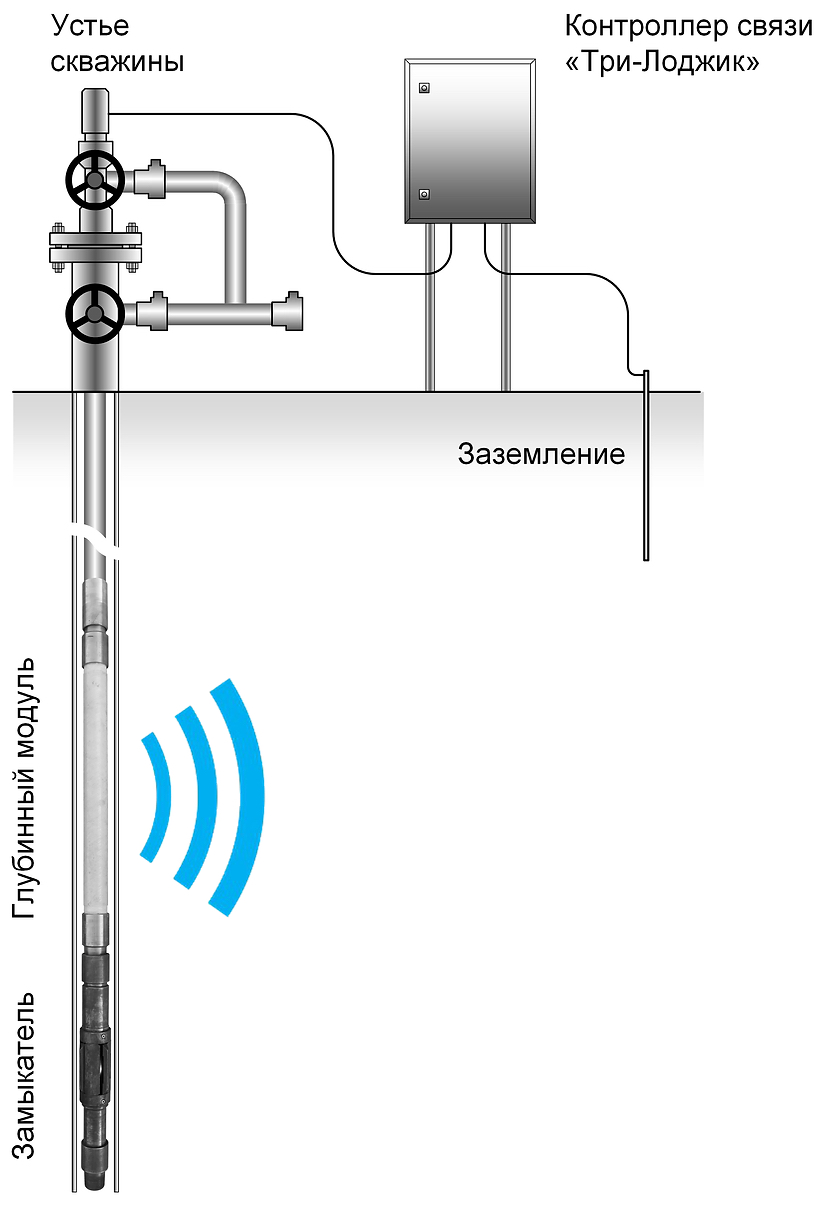

The equipment consists of several main modules. This is the deep device itself with a pressure sensor; battery and antenna. The latter consists of several tubing pipes with dielectric centralizers and a contactor. It provides electrical contact between the device and the production string to transmit information.

The main element is the module for processing and transmitting information, which is know-how. A wellhead station is installed on the surface to receive information. It is connected to the metal part of the wellhead valve and to the grounding device.

“I am glad that the first industrial implementation of our technology took place at Tatneft,” emphasizes Vladimir KALABUKHOV, General Director of Tri-Logic LLC (Skolkovo). – It has limitations on the volume and speed of data transfer. Therefore, we plan to adapt it for those tasks where it will provide the maximum economic effect for the company.”

A cable-free system for monitoring downhole parameters will eliminate the use of expensive cables. In addition, the use of such technology eliminates the failure of downhole equipment due to cable breaks and increases the reliability of the equipment.