The Impact of Invert Emulsion Killing Fluid on Reservoir Permeability and Porosity

This paper describes the impact of invert emulsion killing fluids on reservoir porosity and permeability. 83% of killing fluids in the world oil and gas industry are water-based fluids. The disadvantage of such fluids is a decrease in porosity and permeability after each well killing operation.

Despite the fact that emulsion solutions require strict fire and environmental safety measures, these fluids have many benefits. In particular, emulsion solutions are used in wells where other solutions do not provide a proper quality of physical and chemical impact on oil reservoirs.

Researchers pay a great attention to hydrocarbon-based killing fluids, which have no negative effects demonstrated by water-based fluids.

In the USA the use of hydrocarbon-based solutions is about 17%, in Russia only 0.5%. The basic advantage of hydrocarbon-based fluids is that the water dispersion medium is replaced by the hydrocarbon one. This reduces the chemical interaction of such solutions with the well rock, especially in wells with unstable chemogenic and clay deposits, and significantly reduces capillary forces. Such solutions are characterized by low fluid phase filtration into permeable reservoirs, and high aggregate stability under the influence of downhole temperatures, reservoir fluid and finely dispersed solid phase. Besides, hydrocarbon-based solutions perform well in the conditions of hydrogen sulfide as these solutions are steady against acid gases due to a high absorption ability.

Taking into account the experience with hydrocarbon-based fluid, in this study we carried out laboratory tests of invert emulsion killing fluids using 12 emulsifiers.

Laboratory research was conducted to determine the following criteria.

1. Time for emulsion preparation:

This parameter determines the overall operation performance, the time period when special equipment is involved, the time period of well shutdown, which ultimately affects the economic profitability of the operation.

2. Emulsion stability (emulsion lifetime at a given temperature):

Emulsion stability determines the maximum period of possible well shutdown at which there is no negative impact on the reservoir and deterioration of porosity and permeability, and the reservoir is considered «protected» from the harmful effects of killing solutions and process fluids.

3. Heat stability (maximum temperature at which the emulsion is stable):

4. Chemical agents volume:

This criterion indirectly determines the economic feasibility of the technology, as well as the operation performance.

5. The need to use additional agents (oil, salts, etc.):

This is one of the crucial factors which, depending on the technology and chemical agents, dictates the need to use oil tank trucks, oil, salts, etc. Using additional agents require extra care, safety and environmental protection. At the best case no additional agents are required to prepare the emulsion.

6. The type of emulsion (direct or invert):

The type of the prepared emulsion determines the protective properties of killing fluids. The invert emulsion is an emulsion of the water-in-oil type, i.e. with an external hydrocarbon phase. The direct emulsion is the opposite. The external phase must be hydrocarbon, i.e. the invert emulsion should not cause capillary effect and reduce phase permeability for oil.

7. Emulsion viscosity:

Viscosity is one of the main factors that determine the efficiency of killing fluids. Poor emulsion penetration into the reservoir is due to viscosity. Fluids with higher viscosity require a higher pressure drop for filtration.

Temperature Stability

This test was conducted with each killing fluid sample at 3 temperatures (12°C, 20°C, 25°C), due to different well conditions at different depths.

Figure 2 shows the highest and the lowest temperature stability.

Assessment of the Risk of Insoluble Residues Formation when Mixing the Killing Fluid with Reservoir Fluids

The test is carried out by mixing the studied well killing fluids with formation water/oil in the ratio 75/25, 50/50, 25/75. The resulting sample is mixed by turning the container tenfold and assessed visually for miscibility. Then the sample is placed in a thermal oven with the set formation temperature (25°C) and kept for 14 days. The sample condition is evaluated visually every 24 hours.

Figure 3 shows the best and the worst results on the study of the assessment of the risk of insoluble residues formation.

Physical Simulation of the Impact of Well Killing Fluids on Rock Samples with Various Permeability

Physical simulation is a method of experimental study of various physical phenomena based on its physical similarity. Therefore, during physical simulation of the impact of killing fluids on rock samples it is necessary to create conditions similar to reservoir conditions, i.e. reservoir pressure and temperature at which the fluid interacts with the rock.

The simulation was carried out using the laboratory unit PIK-OFP-1-40-AR/RR provided by Samara State Technical University.

Simulation stages:

1. Saturation of core samples with reservoir water

2. Determination of initial rock permeability for oil

3. Simulation of water-gas fluid penetration process

4. Determination of rock permeability for oil after penetration of water-gas fluid

5. Determination of recovery factor of phase permeability for oil

Results of the physical simulation.

Processing of filtration data is as follows:

1. Determination of a pressure drop before and after injection of killing fluid into the core. These values provide data for further calculation of coefficients of

phase permeability for oil before and after injection of the studied fluid into the core;

2. Calculation of permeability loss factor and core permeability recovery factor after processing of the killing fluid under study.

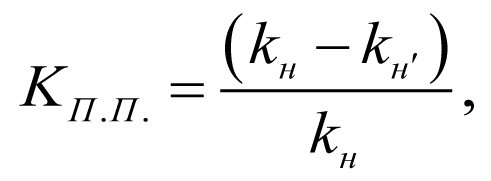

The permeability loss factor ![]() is calculated with a formula:

is calculated with a formula:

(1)

(1)

where ![]() initial rock permeability for oil, m2;

initial rock permeability for oil, m2; ![]() rock permeability for oil after penetration of the killing fluid into the pore space, m2.

rock permeability for oil after penetration of the killing fluid into the pore space, m2.

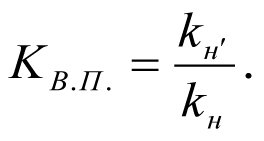

The formula for calculating the permeability recovery factor is as follows:

(2)

(2)

For killing fluids that do not adversely affect the permeability of the bottom hole zone ![]()

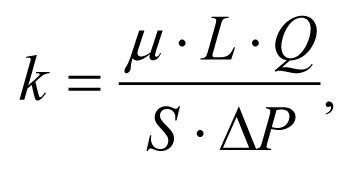

The core sample permeability is calculated with Darcy’s formula:

(3)

(3)

where k – core sample permeability, m2;

μ – dynamic fluid viscosity, Pа-s;

L – length of the core sample, m;

Q – pre-determined fluid flow rate through the core, m3/s;

S – cross-sectional area of the core sample, m2;

ΔP – pressure drop at the ends of the core sample at a given flow rate, Pa.

The main controlled parameter during the test is the change of a pressure drop that provides data for further calculation of the change of the oil mobility after pumping the killing composition.

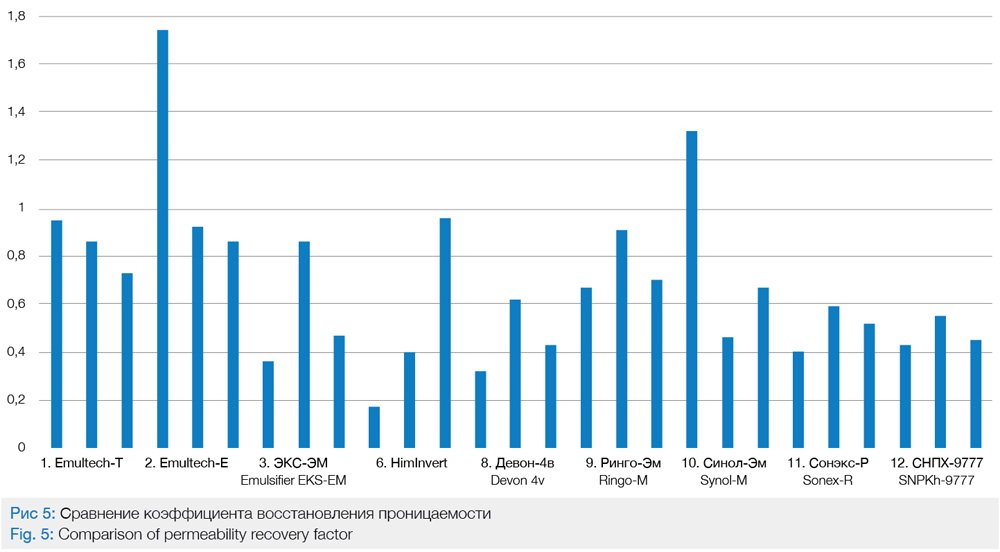

In the vast majority of cases it was found that the killing fluid is not filtered through core samples, which is due not only to high viscosity of the killing compositions, but also to mechanical blocking of small diameter filtration channels with emulsion particles, including channels blocking in narrow and deviated sections. Filtration was only available in samples with high permeability. The highest permeability recovery has been found in fluids Emultech-T, Emultech-E, Ringo-M, Sinol-M fluids (Fig. 5).

Rheology Parameters

For more detailed understanding of reservoir processes during the injection of a killing fluid, studies were carried out to determine static and dynamic shear stress, plastic and apparent viscosity.

Compositions based on emulsifiers were prepared (according to the manufacturer’s recommendations). Table 1 presents the rheology parameters measured using OFITE model 800 viscometer.

Note: Well killing fluids №1 Emultech-E and №2 Emultech-T are the most viscous compositions. Rheology parameters of these fluids cannot be measured using the rotary viscometer. Therefore, the Anton Paar Physica MCR 52 rheometer will be used in the future to determine rheology characteristics.

For Emultech-T and Emultech-E, the effective viscosity of emulsion solutions increases as the shear rate decreases. It can also be noted that at high shear rates the viscosity of the system starts to decrease resulting in spikes on rheological flow curves – this behavior can be explained by reversible short-term destruction of thixotropic structure and relaxation effects. Since there is no layers separation or irreversible system failure, this effect can even be useful when pumping non-damaging killing solutions through the tubing when less than expected pressure is required.

Conclusion: On the basis of these researches on determination of rheology parameters of the killing compositions, these compositions can be classified as non-Newtonian fluids. Emultech-E (#1) Emultech-T (#2) fluids have the highest viscosity. Due to high viscosity measurement of rheology parameters using a rotary viscometer is not possible, therefore it is recommended to perform measurements using a rheometer designed for testing high-viscosity compositions. It was also noted that all fluids have the same static shear stress at 10 min and 10 s exposure.

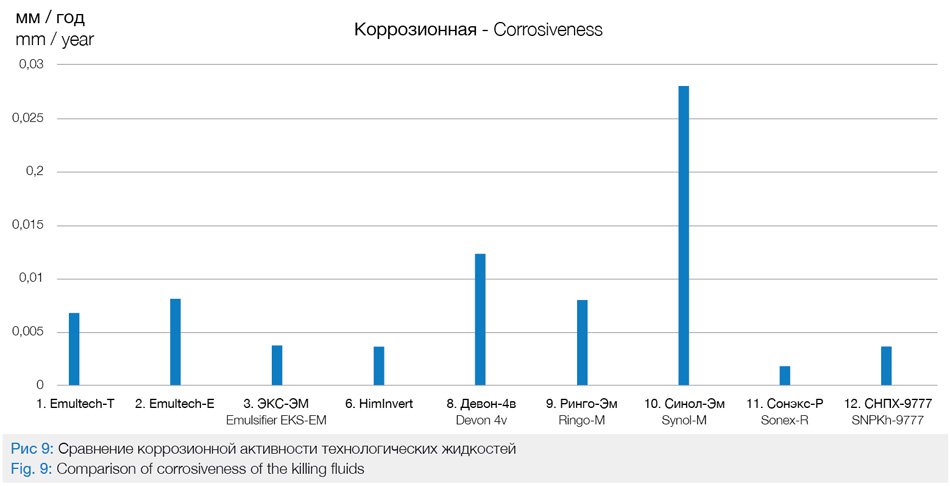

Corrosiveness

Corrosion tests of chemical agents (product form or aqueous solutions) are conducted in accordance with GOST R 9.905. Corrosiveness is evaluated by the gravimetric method by changing the weight of carbon steel samples.

Test samples are St3 carbon steel plates (Figure 6). A 5 mm diameter hole is drilled inside each plate for hanging. The sample surface area is 25 cm2. The ratio of the sample surface area to the agent volume should be at least 1:10 (10 cm3 of the agent per 1 cm2 of the sample area). Thus, 250 ml glass vessels were selected for the test (Fig. 7).

Before testing, the surface of samples is ground to roughness Ra no more than 1.6 microns according to GOST 2789, wiped with cotton wool or filter paper, degreased with acetone, kept for 1 hour in the drying oven and weighed on the analytical scales with an error of no more than 0.0002 g. Then, the prepared samples are fixed in the plant holders in an upright position and put into the test cells filled with the agent (product form or aqueous solution).

The tests are carried out at room temperature for 24 hours depending on the application area of the chemical agent.

Immediately after testing, the samples are visually inspected to determine: the presence and nature of corrosive products, and once the corrosive products have been removed, the nature of the corrosion. In order to determine the loss of the samples mass, the samples surface must be cleaned in the following sequence:

• loose corrosive products are removed with a pallet knife or a pencil eraser.

• if there is a dense film of corrosive products, the removal by chemical method is allowed in accordance with GOST R 9.907;

• the samples are washed with tap water and distilled water, dried with filter paper, degreased with acetone,

packed in filter paper and kept in a drying oven with a dehumidifier for 1 hour, after that the samples are

weighed with analytical scales with an error of no more than 0.0002 g (Figure 8).

Conclusion: Based on the conducted research (Fig. 9) it can be concluded that all the fluids studied, are not corrosive.

Conclusion

According to the conducted researches it can be concluded that invert emulsion killing fluids are the most promising fluids for using at the field. Physical simulation has confirmed the benefits of using these fluids: maintaining and increasing core permeability, temperature stability, low corrosiveness.

It can be noted that these killing fluids have a wide range of applications at various reservoir depths, in reservoirs with abnormally high and abnormally low reservoir pressures, in horizontal wells, in reservoirs developed with hydraulic fracturing technology, in high-temperature reservoirs, in saturation-sensitive reservoirs with permeability reduction, rock swelling and adverse capillary effects.

A significant advantage is the stability of technological properties of the killing fluid for more than 14 days, which facilitates a regular failure-free operation mode.

In conclusion, invert emulsion killing fluids are the best option available on the oil and gas services market. Further research in this area is needed.

References

1. J.R. Grey, G.S.G. Darly. Composition and properties of drilling agents (flushing liquids): translated from English – M.: Nedra (bowels), 1985, 509 pages.

2. Mukhin L.K. Burovye rastvory na uglevodorodnoi osnove dlya bureniya v oslozhnennykh usloviyakh i vskrytiya produktivnykh plastov (Hydrocarbonbased drilling muds for drilling in trouble zones and producing formations completion): D.Sc. Thesis in Engineering – Moscow: Moscow Institute of Petrochemical and Gas Industry, 1971. – 148 p.

3. Klimanova D.A., Mozgovoy G.S., Nikitin V.I., Rationale of usage emulsion fluids as non-damaging killing solutions // Ashirovskie readings, Samara State Technical University (Samara). — 2019, — № 1. — P. 118—121.

Author

Maksim Kurbasov: Chief Technologist, Well Cementing Division, JSC Siberian Service Company

Georgy Mozgovoy: Senior Lecturer, Drilling of O&G Wells Department, Samara State Technical University

Vasily Nikitin: Ph.D., Associate Professor, Drilling of O&G Wells Department, Samara State Technical University