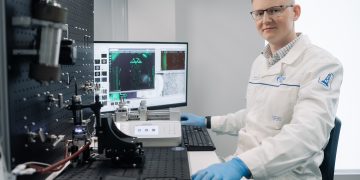

The ROGTEC Interview: Anton Khomutov, Technology Benchmarking Project Manager, Gazpromneft STC

Anton, you have recently started a new role as the Technology Benchmarking Project Manager in Gazpromneft STC. Can you describe what new responsibilities you have and what you hope to achieve in this role?

The major goals that I have set myself are:

Organizing the process of searching, analyzing and setting the benchmark parameters which will measure the efficiency of well construction technologies which we are and will considering using. To determine the need to change the existing benchmark parameters to improve the technology strategy of Gazprom Neft’s drilling and workover operations.

Could you briefly explain what is Technology Benchmarking and what advantages it will bring to the company?

Benchmarking is the process of analyzing benchmarkable metrics, in its essence, it is a competitive analysis between similar companies, vertically integrated oil companies (VIOC’s) in this instance, which highlights the technologies and products which they are currently using to increase well construction profitability and compares their advantages across the range of companies. That is, putting it in other words, technological benchmarking is a search for the best industry leading solutions and the analysis of its success, to adjust the training plans, for those who need improvement on their past performance. I will distinguish three important types of benchmarking which can be used to increase the level of technological development:

• Product benchmarking – measurements and research of products (technological solutions) of other VOIC’s

• Functional benchmarking – the comparison of certain indicator functions and the applied processes to improve the well construction cost ratio performance

• Strategic benchmarking – the study of technological strategies of operators, Russian and foreign.

The expected benefits are:

• Obtaining technological insight and best practices in the field of well construction and the subsequent transfer of results to the Company’s subsidiaries;

• Access to the index of technologies which can be purchased to aid the industry’s development.

The key parameters of this process could be: the increase in the quantity of the products (technological solutions) to increase the profitability of the well construction process, the reduction of internal expenditures for development of the company’s own technological products, and, as an indirect effect, the reduction of well construction costs due to the multiplication of best practices in the industry.

What benchmarking strategy did the company have in place prior to you taking up your new role and what changes will you be bringing to the company’s strategy?

Up to this moment, the company had no initiatives for the development of technological benchmarking. Our company has been actively seeking its place in the world as a company of the “Future”. The company’s long-term vision has been to become a flagbearer for the “smart” energy industry of the future, to shape the progressive transformation of the industry. Among the major principles of the company’s development are – “Efficiency” and “Adopter of Innovative Solutions”, while the tool of the technological benchmarking makes it possible to get an answer to the question “What should we undertaking to become a technology leader?”

How important is executive and senior management support to implement and support a benchmarking initiative?

The goals of subsoil users is to increase the profitability of HC production. The solution is unachievable without the adaptation of new and distinctive engineering solutions which can reduce drilling costs and well operation expenditures. The support from the top management is critical, since the process of technological benchmarking is a collaboration between VIOC technical specialists and top managers with the purpose to achieve a common goal – sharing innovative and technological solutions within the discipline of drilling and workover operations. In any scenario, the task of the top managers is to enable efficiency and growth. In the partnership scenario, in the field of technological benchmarking, is going to help each operator to shape their priorities in the field of technology policies, to understand the demand and adoption of current well construction technologies and to reduce the technical and financial risks of implementing new solutions.

Gazprom Neft is a highly successful operator with many operating units spread across the length and breadth of Russia. How can such a successful oil company not already know what the best technologies and practices are to use in your fields and operations?

Our company’s mission sounds like this: “Develop Ourselves To Develop The World. Build To Be Proud Of Our Accomplishments.”

Working on the development of collaboration in the field of technological benchmarking, we want to share our knowledge of technologies to confidently move to the best achievements. Our company has witnessed the history of its own success in developing the technological paradigm and is ready to translate the best practices to those who have the ambition to become an industry leader.

What are the key technical areas you are looking to set benchmarks for?

We chose the 8 following technological trends for our benchmarking technique:

• Well completion;

• Fracturing;

• Development drilling and workover using sidetracking;

• Coil tubing;

• Drilling fluids;

• Cementing;

• Drill bit servicing;

• Directional drilling.

Could you provide some examples of leading technologies or projects you are looking to implement or learn from?

1) In our company, we actively optimizing our well design solutions to reduce the consumption of metal and the well construction time with technologies capable of reducing the well construction duration. The “Program for Optimized Well Design” was launched in Gazpromneft-Orenburg in 2017, yet currently, each subsidiary of the company increases the efficiency of well construction as part of the design optimization in each field setting. Only in 2019 did we have managed to reduce the CapEx, in the amount of more than 1 bln.rubles, as part of the program for well design optimization in Gazpromneft –Noyabrskneftegas, Gazpromneft-Orenburg, Gazpromneft-Yamal, Slavneft-Megionneftegas, Gazpromneft-Vostok, Gazpromneft-Khantos and Messoyakhneftegas.

2) We continuously strive to increase our competencies in TAML 3 multilateral wells with multistage fracs at low permeable reservoirs in the Achimov formation. The construction of hi-tech multilateral wells, besides the fact that it provides an incremental recovery, reduces the capital expenditures in well pad infrastructure. We distinguish the construction of multilateral wells as a separate technological priority. We also implemented projects for drilling fishbone wells at Messoyakhneftegas, having the maximum number of 9 side holes. The effect of the “fishbone” construction, in terms of the incremental production, amounted to 58 thousand tons of oil equivalent in this subsidiary in 2020.

3) Separately, I can mention the activities in the field of digitalization of the well construction servicing processes of real time: a number of efficient digital products have been created for the regional drilling service centres, namely, Predicting Drilling Problems, Determination of Bottom Hole Lithological Variety, Predicting Well Productivity, using Big Data and AI algorithms.

How will benchmarking identify and reduce bottlenecks and improve performance in your field operations?

Technological benchmarking is an innovative development for VIOCs, making it possible for them to focus their attention on the potential for change. Both the best and the worst cost performance ratios are revealed during benchmarking, which provides a range technologies utilized within well construction. The best result, in terms of the indicators, is provided by the correct selection of the technological solutions and by the availability of a strong culture of working with the technologies, i.e. this result is identified by use of best practices and we then start benefiting from those best practices by replicating them across the company. The worst outcome is a lesson learned which is factored into the design and planning stage of new wells. That is, benchmarking is a tool for selecting the best practices, and as a learning tool, to help reduce the risk of employing technologies with a low potential output.

What dangers are there that KPI’s will simply become a tick list of tasks for teams to say they have completed without implementing the strategy and changes behind the initial benchmark initiative?

I do not see such a risk because one draws up a task checklist to obtain a result – the KPI is the metric of that result. If an operator sets a highly repeatable task – i.e. to use the insight obtained over the course of benchmarking to increase the company’s cost-performance ratios, this shall would cause changes in the technological agenda and the technological paradigm as a whole.

How will the system be practically implemented in your field operations and what level of support and training be given to implement it?

Technology benchmarking, is a separate product and it is created to serve the interests of the operator i.e. oil and gas producing subsidiaries with the purpose of implementing changes in the technological paradigm. The target audience of the operator – from the personnel engaged in well construction planning to the top managers of the companies engaged in the technological management and strategic development. Judging by the format of a future product I can suppose that it’s going to be a communication platform reflecting the result of using engineering solutions on 8 technological trends. As for the product support – the support algorithm is comparable with any information system support process.

How will you monitor, measure, and improve the system over time to ensure its success?

For this we are going to apply standard product metrics – to improve the product using and evaluating the feedback from users, evaluating how long the system was in use, monitoring the dynamics of the quantity of users and the dynamics of the user’s satisfaction index.

How can wider industry collaboration assist and improve technology benchmarking and what improvements would it bring to those who participate?

We hope to involve both the representatives of Russia’s VOICs and the representatives of foreign production companies into the partnership of technology benchmarking. With a larger number of participants in the benchmarking process it will be possible to obtain bigger data on best practices and technological insights. The potential for positive future changes are obvious here, such as – by adopting leading indicators we will enable positive growth of our own well construction cost-performance ratios, as well as forging cooperation with providers/technology developers to create new opportunities for product development or adaptation of turn key solutions.