The ROGTEC Interview: Mikhail Shuster, ASP Facilities Project Manager, Salym Petroleum Development

Since 2013, Salym Petroleum Development (SPD), the company which develops the Salym group of fields in Western Siberia, has been executing a pilot project for chemical flooding on the basis of a three-component ASP (alkali, surfactant, and polymer) mixture. This April SPD successfully completed drilling of wells for the pilot project. In an interview for the ROGTEC magazine, Mikhail Shuster, ASP Facilities Project Manager, speaks about key phases of application of the innovative enhanced oil recovery (EOR) technology, the project’s key targets and challenges.

I understand you are the ASP Facilities Project Manager at SPD – tell us a bit about your role and what your short and long term goals are.

The role of the project lead within the scope of the ASP project is multifaceted. It includes several key functions. First, it is to ensure protection of health, safety, security, and environment (HSSE); second, planning of all processes within the ASP project; third, ensuring correctness of technical solutions and infrastructural facilities design. In addition thereto, I am responsible for the development of contracting strategy and preparation of contracts and agreements, arrangements for research and development, generation of the budget and supervision of its utilization, quality assurance, development and implementation of human resource plan, as well as arrangements for testing and commissioning at ASP facilities. I would also like to note that, taking into account the complexity of the ASP project and multidisciplinary nature of the tasks it solves, its execution would be impossible without the ASP project team and assistance from all divisions across SPD.

As it pertains to goals and tasks we are to solve within the scope of the APS project, our short-term goal is the safe and quality execution of the pilot ASP project on West Salym field in compliance with the pilot project budget and timing parameters set forth by the shareholders. We are to practice this technology in actual field conditions, demonstrate its advantages, and assess potential risks and opportunities for its further scaling. SPD’s long-term goal is a full-field implementation of ASP technology on West Salym field. Within the scope of our strategy, a long-term plan for phased implementation of this technology on the field has been developed; however, it must be taken into account within this context that a full-field implementation of ASP is only possible with changes in the tax regime applied to Russian Federation subsoil users. Without tax incentives, full-field implementation of ASP technology is economically unfeasible due to high capital and operating expenses.

ASP is a relatively new but promising EOR method. Tell us how is your pilot project going? What results have you achieved/are expected?

First of all, I would like to explain the value of applying EOR and chemical flooding methods – in particular, ASP-based.

In 2050, the global demand for energy products may double or even triple vs. 2000, taking into account further development of modern industries in the economy. Due to the fact that the huge energy deficiency will not disappear, oil and gas will play the leading role in the global energy sector and chemical industry for as long as several decades. At the same time, older fields are in decline, which makes the issues of finding new reserves and enhancing oil recovery in the course of their development even more relevant. Therefore, the high demand for hydrocarbons sets forth tasks which must be solved through efficient and innovative methods – these are, in particular, EOR methods.

The era of ‘easy oil’ is drawing to a close in Russia. The fields in Western Siberia, which yield more than a half of Russia’s oil, have entered the phase of production decline; water cut on many fields exceeds 90%, while development of new reserves concentrated in difficult geographic, geologic, and climatic conditions is associated with high risk levels and the need for large-scale investment. State-of-the-art production technologies including EOR methods make it possible to enhance oil recovery factor (ORF) and produce oil which several decades ago was believed to be impossible to recover. Research results have shown that ORF enhancement on a global scale by mere 1% will make it possible to increase conventional oil reserves to 88 bln barrels, which is three times as much as they currently produce in a year.

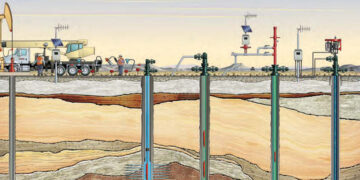

ASP technology is indeed an enhanced oil recovery method which fosters the enhancement of oil recovery factor. With ASP technology, The ASP components are dissolved in water and injected into the oil producing formation. The surfactant reduces the surface tension between oil and water. Alkali protects the surfactant. And polymer is used to increase the viscosity of the mixture. The effect of integrated usage of these components is similar to what happens when a detergent washes grease off a frying pan. ASP technology has already yielded practical results in the USA, Canada, Oman, and China.

SPD has been studying the ASP technology since 2008. It has completed series of laboratory and field tests, with impressive results. The use of the technology in a single well tracer test demonstrated the displacement of 90 percent of the oil left in the formation after waterflood. We have been executing a pilot ASP project since 2013. SPD has successfully completed drilling of 7 wells for the pilot project recently. In addition thereto, we started construction of ASP pipeline and ASP mixing unit, the completion of which has been scheduled as early as by the end of this year.

There are statistics suggesting using ASP over conventional water flood techniques could increase the recoverable oil by up to 20%. Are you seeing this increase in reality out in the field?

It will only become possible to speak about actual indicators after the execution of the pilot project and obtaining of first results. At the same time, ASP technology has been applied on oil fields in various countries of the world including China, India, Canada, and the USA. Following the results of the application, ORF gain on these project has been evaluated to be 10-20% of initial oil in place vs. conventional waterflooding.

An important distinguishing feature of ASP technology is the fact that, taking into account similar geologic characteristics of fields in Western Siberia, it can be replicated on other oilfields in the region as well. As calculated by experts, ASP-based chemical flooding technology may assist in producing additional 2.4 bln tons of oil across Western Siberia within the next 20 years. This is a huge volume taking into account the fact that annual production in Khanty-Mansi Autonomous Okrug – Yugra today is about 260 mln tons.

Some EOR techniques have, in the past, been the cause of environmental concern. How are you ensuring environmental compliances on your EOR project?

First of all, I would note that tertiary oil production methods including ASP injection-based chemical flooding, make it possible to use natural resources in a more efficient manner. Conventional methods only make it possible to produce 30-40% of initial oil in place; the remaining hydrocarbon volumes rest in the formation. The development of technologies to enhance oil recovery factor is a priori focused on a more intensive utilization of resources available.

In addition thereto, ASP, as compared to other oil production projects, is a more wasteless technology. Usage of the existing infrastructure and existing wells makes it possible to minimize environmental footprint as well as substantially reduce additional waste generation per ton of additional oil production.

On a separate note, the components in the ASP mixture are non-toxic. They are used in household chemistry (alkali and surfactant) and water treatment (polymer). For comparison: toxic level and maximum allowed concentration codes for all components do not exceed MACs for crude oil.

SPD is executing the APS project in strict compliance with all nature preservation requirements. The project has successfully passed environmental expert assessment and obtained the full set of PLA.

How does the regions climate affect your ASP project, and in particlualar the properties of surfactant? Do the cold temperatures limit

the use, storage, mixing and distribution of ASP mix?

We have specially considered the issue of climatic conditions in Western Siberia in the course of designing the pilot ASP project infrastructure. Thus, the surfactant to be applied within the scope of the pilot project is in fact a virtually solid substance at 0°C. As far as we are concerned, this of course called for development of special technical solutions. All project and technical solutions have been developed taking into account the higher requirements determined by the geography of the West Salym field location, and make it possible to continuously and safely operate process facilities 24/7 under any weather conditions possible in the Khanty-Mansiysk Autonomous Okrug – Yugra.

ASP looks like a key to unlock the rich hydrocarbon reserves of Western Siberia. Why have other oil companies not activelyused EOR methods, including ASP?

No doubt that enhanced oil recovery-focused projects are interesting for many Russian oil companies. However, these technologies require a very thorough engineering and adaptation to local development conditions.

SPD is the leader in this sphere in Russia. This position is in particular ensured by the powerful research and development potential of the shareholder companies – Shell and Gazprom Neft. Shell has a proprietary research and development unit in Rijswijk (The Netherlands), while the Russian oil company specialists work on the premises of Gazprom Neft Scientific and Technical Center.

It is important to understand that state of the art technologies are costly; they often require the creation of unique competencies and a ramified infrastructure. Due to this fact, the production cost of such oil is much higher than conventional. Active execution of similar projects in Russia requires the involvement and efforts on behalf of companies as well as incentives and support on behalf of the state.

As I noted early in the interview, full-field implementation of the ASP technology has no economic feasibility without provision of tax incentives. Jointly with our shareholders, we have prepared several proposals on this issue, and submitted them for review by relevant state authorities. In case certain tax incentives are established, ASP application will make it possible to prevent production decline in the key oil producing district of Russia as well as create hundreds of new jobs and raise investment for dynamic development of related industries in the region such as petro chemistry and hi-tech oilfield services; that is, the effect of ASP application will be manifold. Active application of this technology is a win win situation for everyone – companies, state, and community.

Besides ASP, SPD also focuses on the development of the Bazhenov formation that is very promising in terms of horizontal wells and unconventional development. What plans do you have for the harder to recover reserves in this formation? Are we to see large scale development of Bazhenov’s “hard to recover reserves” from SPD in the very near future?

SPD has been involved in a large-scale theoretical and practical work towards studying Bazhenov formation development methods since 2003 when the development of the Salym group of fields started. Within as little as the last three years, the company has drilled three vertical appraisal wells, performed 3D seismic, retained a core, performed a broad set of geophysical studies, as well as executed an extended testing of two wells in order to evaluate production outlook for the Bazhenov formation.

In the course of our studies we have come to the following conclusion: the most efficient technology among the solutions tested in the course of development of deposit with properties similar to those of the Bazhenov formation is to drill horizontal multiple frac wells. This formation stimulation method is currently actively applied for oil production from low permeability reservoirs all over the world. The essence of the technology is consecutive execution of several fracs in a single horizontal well. As a result of this work, cracks are formed in the formation, through which proppant – a pellet-type material – is injected into the well, which prevents closure thereof. Presence of such cracks makes it possible to substantially enhance formation conductivity and therefore increase the well drainage area and the volume of hydrocarbons recovered from the formation.

As you know, at the end of 2013 SPD spudded the first one out of three horizontal Bazhenov formation appraisal wells. In 2014-2015, the company will perform a multi-stage frac and the required set of well tests there. This will make it possible for our specialists to obtain data on the initial flow rate and evaluate the potential of the Bazhenov formation in detail. We are currently looking forward to receiving the first results provided to us by construction of first wells.