Udmurtneft: Application of Fibre Glass Tubing

Introduction

The fields at Udmurtneft are at the late stage of development, which is characterised by a high water cut and also the corrosiveness of the produced fluid, which are the main reasons for a considerable number of downhole pumping equipment failures caused by corrosion. The use of fresh surface water at most facilities has resulted in contamination of the pay zones with sulphate reducing bacteria (SRB) and in the occurrence of hydrogen sulphide which is the most corrosive component in the produced and transferred fluids. The chosen optimum method of corrosion protection is corrosion inhibitors and combined biocides inhibitors which allow us to extend the service life of the oilfield equipment. However, as the amount of H2S rises and the oilfield fluids become contaminated, there is still a need for further corrosion protection.

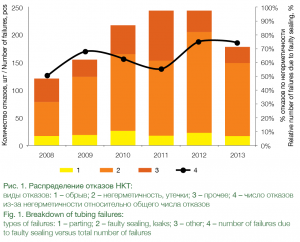

According to the statistical data, about 40% of all failures caused by corrosion at Udmurtneft are in the tubing. The main reason is the tubing’s faulty sealing (Fig. 1) caused by corrosion of the string body or the thread. Tubing corrosion leads to early well shutdown, accidents and, as a result, a higher cost of production of highly viscous oil. Reducing the number of failures caused by tubing corrosion will allow us to considerably reduce the total number of failures and increase the run time of the downhole equipment.

Lately, there’s been a rising tide of interest in fibre-glass pipes that are characterised with high strength and resistance to the impact of corrosive environments. Also, as the prices of metallurgic products have risen, the cost of fibre-glass pipes is now approaching the cost of corrosion protected steel pipes. Therefore using fibre-glass tubing at Udmurneft is a complete solution to the problem of tubing failures and extending run time in complicated production conditions.

Operational Advantages of Fibre-Glass Pipes

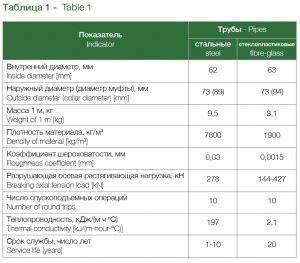

Oil producing companies are very interested in fibre-glass pipes because of their technical characteristics (Table 1) [Ref. 1].

Thanks to its properties, fibre-glass tubing has a number of significant benefits in comparison with steel tubing.

» Inertness to corrosive components (such as acids, salts, alkalis, H2S and oxygen-containing compounds) and, therefore, no corrosion processes, which excludes contamination of the oilfield equipment and near-wellbore area with corrosion product in the form of ferrous sulphide.

» Low weight of fibre-glass.

» The smooth surface of fibre-glass pipes inhibits the creation of scale and paraffin crystallisation nuclei, thus reducing the risk of their formation, which, in turn, reduces the flow resistance to return circulation.

» No plastic yield, but good strength characteristics.

» Low thermal and electric conductivity factors.

» The service life of fibre-glass tubing is more than two times longer than that of steel tubing.

The above-listed benefits have defined the prospects of introduction and industrial application of fibre-glass tubing at Udmurtneft fields.

The Results of Industrial Introduction of Fibre-Glass Tubing

At many assets of OAO NK Rosneft, fibre-glass pipes in injection wells have been operated for over 6 years, but in OAO Udmurtneft, however, FG pipes were first used in 2010 in production wells equipped with electric centrifugal pumps. Now in OAO Udmurtneft more than 120 wells have been equipped with fibre-glass pipes, of which 46% are production wells, 15% are disposal wells, and 39% are injection wells. Using the fibre-glass tubing allowed us to increase the producing wells’ run time two-fold plus (Table 2). As can be seen from Table 2, corrosion-resistant equipment has been introduced in the wells with high corrosiveness of the produced fluid, low run time and large number of failures caused by tubing corrosion. However, in some wells, e.g. in Well 8 at the Mishkinskoe field, after introduction of fibre-glass tubing, failures caused by corrosion of downhole pumping equipment have been observed. In such cases, an integrated approach must be used that combines using anti-corrosion equipment and corrosion inhibitor to protect the steel downhole pumping equipment. This approach has been widely used at Udmurtneft.

Listed below are some problems identified during operation of fibre-glass tubing [Ref. 2].

1. Makeup and breakout of pipes are performed by hand using specialist torque wrenches with specific force and torque;

2. In breaking out fibre-glass pipes process during repairs, a large force has to be used sometimes, which may lead to fibre-glass damage (Fig. 2a) and marks left by the wrench on the pin (Fig. 2b).

To prevent such situations, using a special lubricant with good lubricating and antisticking properties is required, in particular the lubricant offered by the fibre-glass tubing manufacturer.

3. Round trip operations are performed using a steel tubing hanger, which may result in breaking the tubing thread (wear, chipping) in the bell and spigot section (Fig. 3).

Thus, fibre-glass tubing is currently not fully adapted to working with standard tools used for well servicing and workover. Because of the above-listed problems, the average number of FG tubing round trips does not exceed 3. For the period of its industrial introduction in 12 wells (or 22%) of the producing well stock, there were problems with threads during round trips or thread breakages.

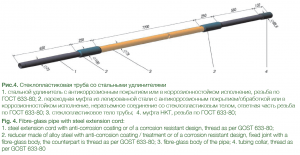

To increase the number of round trips to that stated by the manufacturer, OAO Udmurtneft engineers together with the manufacturer’s engineers have developed a special design of the fibre-glass pipe with steel extension cord (Fig. 4) that allows to increase the reliability of the FG tubing thread section. In August 2013, the first tubing hanger was introduced that used this redesigned pipe (Fig. 4, 5).

It is anticipated that using fibre-glass tubing with steel extension cord will allow us to substantially increase the number of FG tubing round trips, reduce the costs of replacement of pipes with broken threads, which, in turn, will increase the efficiency of pipe products application.

Conclusion

The accumulated 5-year experience of using fibre-glass tubing in OAO Udmurtneft has validated their high process efficiency. For 44 wells of the reservoir pressure maintenance system equipped with FG tubing, the run time has increased to 2000 days and more; for production wells, there has been the twofold plus run time increase , and the number of failures caused by tubing corrosion has decreased, which results in lower oil production losses and a longer tubing operation resource.

The problems that occurred with the thread sections of the pipes during round trip operations will possibly be resolved through the addition of steel extension cords to the FG tubing; this design is now being tested in the field.

Introduction of the fibre-glass equipment, thanks to its unique properties, will be continued in the future in OAO Udmurtneft wells producing corrosive formation fluid.

References

1. TU 2296-001-26757545-2008. Truby stekloplastikovye nasosno- kompressornye, obsadnye, lineynye i fasonnye izdeliya (Fiberglass, oil-well, casing, line and fittings tubes).

2. Malykhina L.V., Mutin I.I., Sakhabutdinov K.G. The experience of application of fibre-glass pipes in OAO Tatneft // Neftyanoe khozyaystvo. – 2009. – Issue 4. – Page 99.

Y.A. Gavrilyuk, A.A. Agafonov (OAO Udmurtneft),

D.A. Nazarov, V.K. Miller (ZAO Izhevsk Petroleum Scientific Centre)

The article was published in the ROSNEFT Scientific and Technical Newsletter (Nauchno-technicheskiy Vestnik OAO “NK “Rosneft”) No.1, 2014, pp.44.

Printed with permission from the Editorial Board.