Uzbekneftegaz Has Fully Commissioned the Drilling Control Center

For the first time in the country, Uzbekneftegaz has fully commissioned the Drilling Control Center (DCC). This was reported by the press service of the Ministry of Energy of the Republic of Uzbekistan.

Theses of the Ministry of Energy of Uzbekistan:

during the opening ceremony, a teleconference was established with the Well Construction Control Center located in the Russian city of Muravlenko, which provides remote engineering support for accelerated drilling processes, and well No. 326 of the Dengizkul field;

Russian specialists spoke in detail about their activities and the results achieved when drilling well No. 326.

Let us recall that in 2020, Gazprom Neft launched a central control center and a production control center (PCC) in the city of Muravlenko to maximize the efficient implementation of the potential of Gazpromneft-Noyabrskneftegaz assets.

Joint DCC project with Gazprom Neft

In October 2023, on the sidelines of REN-23, Gazprom Neft entered into an agreement with Uzbekneftegaz, which was aimed at optimizing the processes of drilling wells in the fields of Uzbekistan. It was noted that within the framework of the agreement, Gazprom Neft – Noyabrskneftegaz will develop a set of engineering approaches and solutions, which will include: supervision (ensuring the optimal process) of drilling, audit of drilling equipment, recommendations for changing the design of wells, selection of the optimal formulation of drilling fluids.

The companies also considered the possibility of creating a central control center in Uzbekneftegaz using the software of Gazprom Neft and its specialists in the field of well construction. According to the Chairman of Uzbekneftegaz B. Sidikov, the initiative to create such a center based on studying the experience of international companies has been worked out for several years, and a decision was made to implement the project together with Gazprom Neft.

Objectives of the Central Management Department of Uzbekneftegaz:

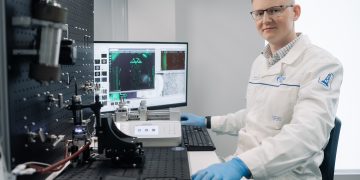

- monitoring of drilling processes in real time;

- prompt identification and prevention of possible accidents and emergencies (thanks to the digitalization of drilling operations, modern technologies and remote monitoring systems);

- reducing the duration of drilling wells by 45% and reducing the cost of their construction by 35%, on the construction of each well it will be possible to save from the design cost from 4.0 billion soums (more than 300 thousand US dollars) to 10.0 billion soums (more than 750 US dollars);

- training, retraining and advanced training of personnel: currently, the center’s employees are improving their experience using special software specializing in engineering accounting.

The process of transferring data to the Central Database:

- data on the main parameters of drilling modes is transmitted from each drilling rig in real time;

- incoming data is visible on the company server located at the head office;

- using specialized software, data from drilling sites is displayed on the screen in the form of parameters and diagrams.

Since May 15, 2024, the Central Management Bureau has been monitoring 24/7 the drilling process of 23 rigs at the Dengizkul, Zevarda, Yangi Tegirmon, Shurtan, Lower Eastern Berdak and Lower Surgil fields, located in remote areas of Uzbekistan. Specialists analyze data obtained from drilling sites and develop recommendations to improve the efficiency and safety of the well construction process.