Varyeganneftegaz: Increasing Production with Smart Well Completions

M.S.Kuvakina (Varyeganneftegaz JSC)

Introduction

Recently, Russian oil and gas companies have been actively implementing horizontal wells during field development. Such wells allow increasing the reservoir contact area with well, raising the production rates and performance, as well as increasing the oil recovery factor (OR) from the field as a whole. Despite the development of drilling technologies, there are still issues, related to the construction and completion of horizontal wells, for example, the selection and correct use of inflow control devices to develop the fields with contact reserves.

The Van-Yegan oilfield is unique, located in Western Siberia, in Nizhnevartovsk district of Khanty-Mansisk Autonomous Area. In the field there are 73 productive reservoirs; they contain oil, gas and condensate. About a third of all oil reserves of the Van-Yegan field are contact ones, i.e. they have direct contact with water or gas (oil rims, accumulations with gas caps, reservoirs with underlying water).

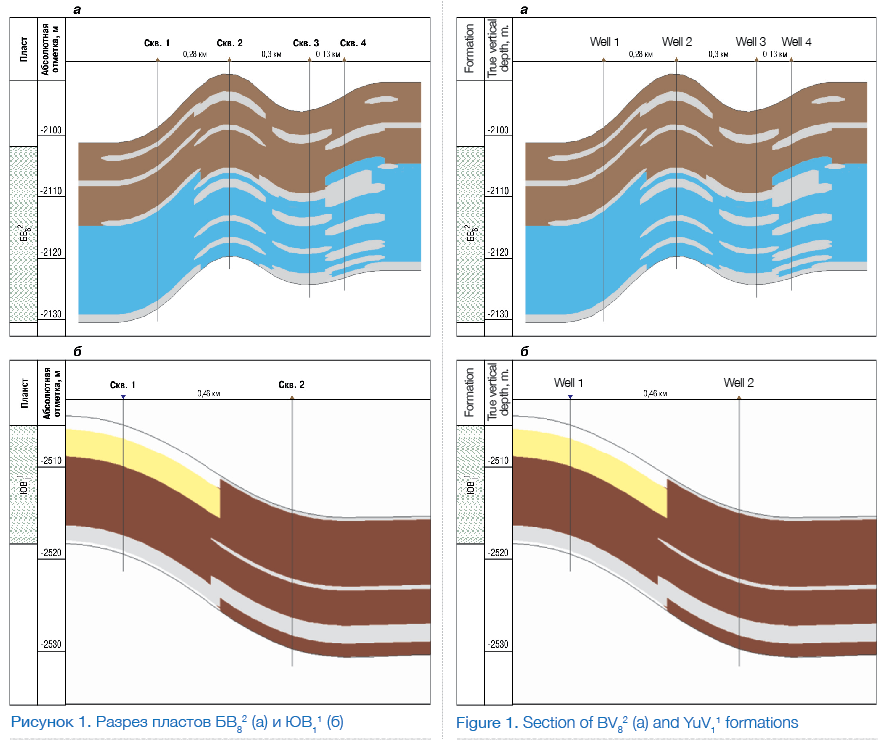

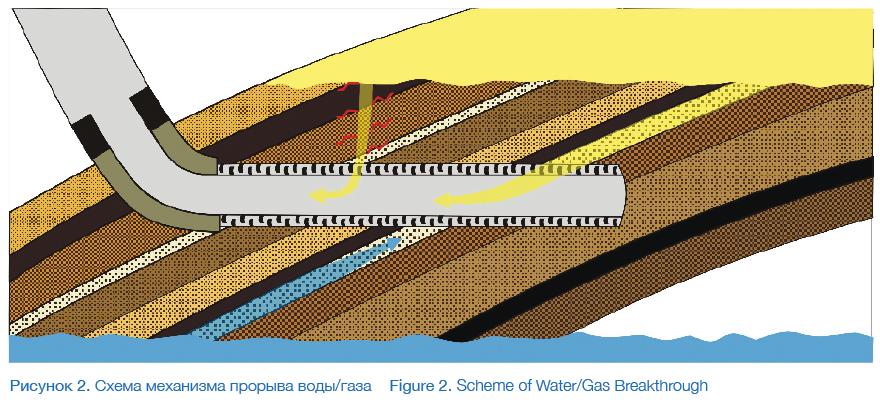

The article covers two formations of Van-Yegan field: BV82 and YuV11. The oil accumulations have contact with underlying water (BV82 formation) and gas cap (YuV11 formation) (Fig. 1). The average current oil saturated thickness of BV82 and YuV11 formations, are of 4 and 5 m respectively. The formations are characterized by a high level of heterogeneity in terms of permeability: permeability of different parts of a wellbore might vary by 100 times, resulting in the risk of water or gas migrations along the highly permeable interburdens. In addition, there is a possible gas breakthrough perpendicularly to stratification (Fig. 2).

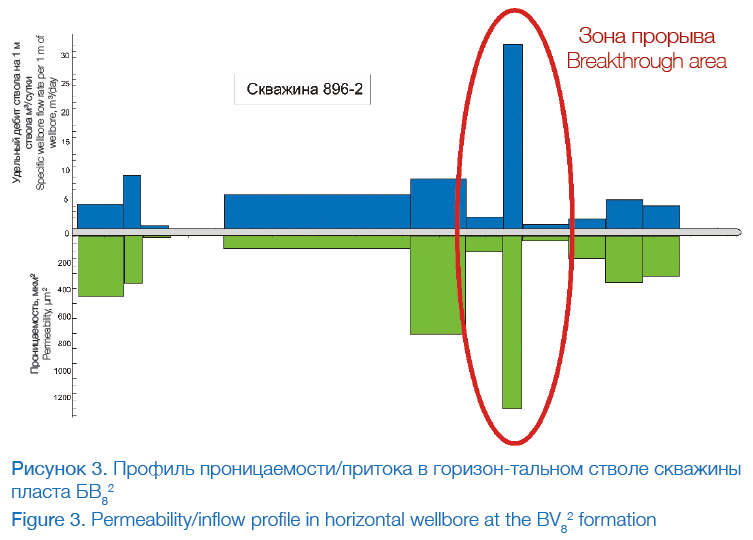

As an evidence of possible breakthrough of non-targeted fluids and irregularity of inflow profile, a calculation was made for permeability profile for several horizontal wellbores and the Joshi formula was used to build a specific fluid flow per 1 m of wellbore. As a result, a highly permeable area has been identified that could potentially serve as a conduit for the water/gas breakthrough (Fig. 3). The consequences of a breakthrough are unequal distribution of depressions along the horizontal wellbore and the low efficiency of the fields development.

Early breakthrough of non-targeted fluid is proved by the actual well performance: water breakthrough in BV82 formation occurs in the first few months after the well’s operation; high gas factor is revealed at YuV11 formation.

There is a difference between the bottomhole pressure at the heel and toe of the horizontal wells due to the fluid friction at the extension pipe. However, the hydraulic calculations, based on the Darcy-Weisbach equation, showed that small pressure losses (less than 0.1 MPa) cannot significantly affect the distribution of a depression and inflow profile in the horizontal section of the well [1].

Therefore, the determining physical effect that leads to heterogeneity of flow at the selected areas is the heterogeneous reservoir properties in the intervals, crossed by the wellbore.

Based on the calculations and analysis of well production for BV82 and YuV11,an optimal solution for early water/gas breakthrough is well completion which considers the geological and rheological properties of deposit and technological features of the wellbore.

Inflow Control Technology in Horizontal Wells

Currently, there are two main types of passive inflow control devices on the oil&gas equipment market, using different mechanisms for creating additional resistance from the reservoir inflows: one is of pipe& screw type and another is of choke type. The main disadvantage of pipe&screw control device is a high risk of early blockage of screw channels; as for the choke mechanisms, there is a high flow rate of the fluid passing through the choke, which significantly increases the risk of corrosion. At the same time, using the above-mentioned flow control systems for development of the oil rims with a massive gas cap allows only postponing a gas breakthrough. In case of gas breakthrough in the well, such systems do not reduce gas inflow, and therefore, either it is required to reduce the pressure on reservoir, thereby, reducing the production rates either to ensure periodic well stops, or to withdraw a well from production operations [2].

Smart wells (hydraulic systems for bottomhole applications) is an example of active control devices, available in the market. Its advantages include a valve position control for each zone, operated from the surface: in case of water or gas breakthrough, it is possible to shut-off one of sections. The disadvantages are low reliability (if one of control lines stops operating, a well can be “lost”), high cost of implementation, long time for equipment delivery and installation complexity.

To resolve these problems, one needs to create a new generation of completion systems, which would take into account the shortcomings of existing inflow control systems, as well ensuring inflow profile, delaying the time of gas breakthrough, and also reducing the flow rates of non-targeted fluids, thereby, increasing the time of crude oil inflow [3].

New Generation of Inflow Control Devices

The Russian engineers from the Wormholes company developped a new generation of passive inflow control devices (ICD)- a soft choke. It was designed to improve the effectiveness of well completion systems at the Tyazhpressmash plant. This device is a sand wire filter with base tube and ICD camera with a network of channels for the fluids to pass. Soft choke ICD Camera allows increasing the hydraulic resistance of moving fluids in a smoother way due to repeated changes of direction, acceleration and braking, merger and division of flowing stream (Fig. 4).

Soft choke system has the following advantages:

» a standard soft choke has from 2 to 12 inlet openings with large enough diameter that significantly reduces the risk of blockage in the system, compared to other systems;

» possibility to change the system configuration prior to lowering it into the well due to inclusion of a certain number of rings with the required wall thickness and number of walk-through holes with optimal phasing;

» durability of the system: the soft choke ICD ensures pressure reduction due to a larger tract of the flow hydraulic resistance at moderate flow rate;

» possibility of installing the ICD system in injection wells to align the injection profile in multilayer systems, while the well might be put into operation and changed to injection mode without changing the completion system [3].

An important condition for well completion with soft choke is a separation of horizontal wellbore into segments, using the swelling/automatic packer with purpose of preventing the cross-flows beyond the casing.

All passive inflow control devices shall be configured depending on the distribution of reservoir properties, based on geological and hydrodynamic simulation and final logging after the drilling operations. It is associated with certain risks, arising from possible errors in geological models, incorrect interpretation of geophysical data, risk of non-achieving the target depth, as well as changing inflow, which is typical for developing the contact reserves with use of horizontal wells. In this case, there is a risk of early gas or water breakthroughs that is almost impossible to prevent- it is only possible to delay the breakthrough for a certain period of time [4]. Subsequently, it is required to reduce the depression on reservoir or to stop the well from time to time, or even to withdraw it from operations. This factor is particularly important when developing the Van-Yegan field, as there is no infrastructure for gas transport or utilization.

In order to resolve this problem, the Russian engineers have also developed an additional option for the soft choke- an adaptive system, which is suitable for developing the oil rims by horizontal wells. This system can be self-adjusted, depending on speed, fluid pressure and its phase structure. Special-purpose valves (Fig. 5) regulate the volumes of inflow: «Adaptive system» allows limiting the maximum flow through each filter at a certain level, regardless of pressure difference. Therefore, the system provides an opportunity to align the inflow profile and to delay the moment of gas breakthrough; in addition, it reduced the gas flow to the breakout area, providing long-term well operation without significant increase of gas factor.

In-built fluorescent tracers for the filter ensure the monitoring of smart completion systems. One part of the in-built tracer is dissolved upon contact with water, the other one- when interfering with oil. Color marking tracers relate to a specific segment of the horizontal wellbore, allowing defining the operation at each section.

Conclusion

Therefore, the main factor responsible for pre-term water/gas breakthrough in the well from reservoir BV82 and YuV11 at the Van-Yegan oilfield, is a lack of reservoir heterogeneity in terms of permeability. The gas breakthrough in YuV11 is also possible perpendicularly to the stratification. It is possible to use the soft choke to align the inflow profile and to ensure a uniform development of the oil reserves from accumulations with underlying water reservoir in the BV82 formation. The best completion option for the YuV11 formation is to use an ICD with adaptive system that would limit the inflow of gas and increase the well operation time with low gas factor.

The proposed completion systems will significantly extend the well life cycle, increase the recovery and significantly improve the economic indicators of the development.

References

1. Semenov A.A., Islamov R.A., Nukhaev M.T., Design of Inflow Control Devices At Vankor field (in Russian). Oil Industry, 2009, no. 11, pp. 20-23

2. Antonenko D.A., Murdygin R.V., Khatmullina E.I., Amiryan S.L. Estimation of Efficiency of Inflow Control Equipment for Horizontal Wells (in Russian). Oil Industry, 2007, no. 11, pp. 84-87.

3. Nukhaev M., Zhuravlev O., Shchelushkin R., Andrianov O. Specific Features of Horizontal Drilling Equipment (in Russian). Neftagaz, 2014, no. 4, pp.

20-24.

4. Semenov A.A., Kiselev V.M. Modelling the Horizontal Well Operation in Conditions of Non-Homogeneous Reservoir Properties (in Russian). Engineering&Technologies, 2011, no. 4, pp. 429-437

The article was published in the ROSNEFT Scientific and Technical Newsletter (Nauchno-technicheskiy Vestnik OAO “NK “Rosneft”) No.1, 2015, pp.36. ISSN 2-74-2339.

Printed with permission from the Editorial Board.