Why Collaboration has a Higher Impact on Business Performance than Technology

For Part One of this article click HERE

Why Collaboration

Geosteering requires sophisticated technologies, access to relevant data (streamed real time data and model derived data) and most importantly, collaboration of geosteering team members. Whilst the first two components of geosteering have broadly been described, analysed in depth and their impact on the geosteering final outcome evaluated in detail, the latter, for unidentified reasons, has not broken through to the wider audience of the upstream industry.

It has recently become clear, even for technology driven industries like oil and gas, that collaboration has a great impact on overall business performance. Astonishingly non-tangible factors like the decision-making process, communication, culture of knowledge sharing, or lean internal work processes have a higher impact on overall team performance than purely tangible factors like the application of cutting-edge LWD technologies, automation of the drilling process or modern data analytics systems. Obviously, the application of such technologies can boost already existing means of collaboration, but these innovative tools on their own will neither have the same effect nor create team collaboration. From the author’s personal experience, enhanced collaboration generated through objectives and KPIs alignment between the Drilling and Subsurface department (theoretically a non-expensive and easy thing to undertake) will have a bigger impact on the Net Present Value (NPV) of a project than usage of ultra-deep azimuthal resistivity tool for well placement (Nordsøfonden, 2019).

A great example of understanding this mechanism is the giant oil and gas company Shell (which employs 150,000+ people), which despite being at the forefront of technological innovation, still makes collaboration a high priority (Customer stories, Microsoft, 2018). Collaboration is at the heart of every single business and with a 36% impact on overall business performance, it is hard not to make it a priority (Frost and Sullivan, 2006).

According to the mentioned report, collaboration will impact:

• Profitability by 29% (e.g. profitability of a project that involves drilling multiple horizontal wells in a field).

• Profit growth by 26% (e.g. profit from each horizontal well or from a project).

• 41% of forces driving stakeholders’ satisfaction (e.g. governments, partners, service companies, contractors’ satisfaction).

• Productivity by 36% (e.g. drilling 8 wells within the budget of 7 well project or increased well hydrocarbon productivity [PI – productivity index] through optimally placed wellbore).

• Product quality by 34% (e.g. wellbore that produces at rates higher than anticipated due to its placement).

• Product development by 30% (e.g. smooth controlled geosteering process that continuously assures optimally placed wellbores).

• Innovation by 30% (e.g. this would include a “must-have” versus “nice-to-have” exercise for the implementation of cutting-edge technologies as well the implementation of

innovative solutions which actually create value).

Drilling Faster Equals Geosteering Faster

In the current post oil crisis economic environment, dominated by high oil price volatility and uncertainty about the future of fossil fuels, the average cost of drilling a horizontal well is absurdly high. An immediate way to mitigate this (and indirectly obtain a low breakeven cost of oil and gas production) is to drill horizontal wells faster. Wells being drilled all around the world take a fraction of the time they took to drill many years ago. It is mainly speed that keeps the industry afloat. As the operations teams are drilling wells faster, they are also required to geosteer them faster. Not surprisingly, this creates problem for geosteerers.

At high rates of penetration (high ROPs) and with huge pressure of responsibility and time, a few minutes of doubt or an incorrect decision can considerably affect the overall contact with the reservoir and consequently geosteer the well out of the “sweet spot”. In the middle of that fast-paced process a geosteerer must digest an incredible amount of information and synthesize it into clear and accurate instructions for the direction of the well. Yet a geosteerer does not perform this task in isolation. Collaboration with the entire geosteering team and deriving expertise from all involved disciplines is a must for the ultimate success of the process. This means that “fast” geosteering requires more effective and more efficient collaboration in the geosteering team that will support this process in the most optimal way.

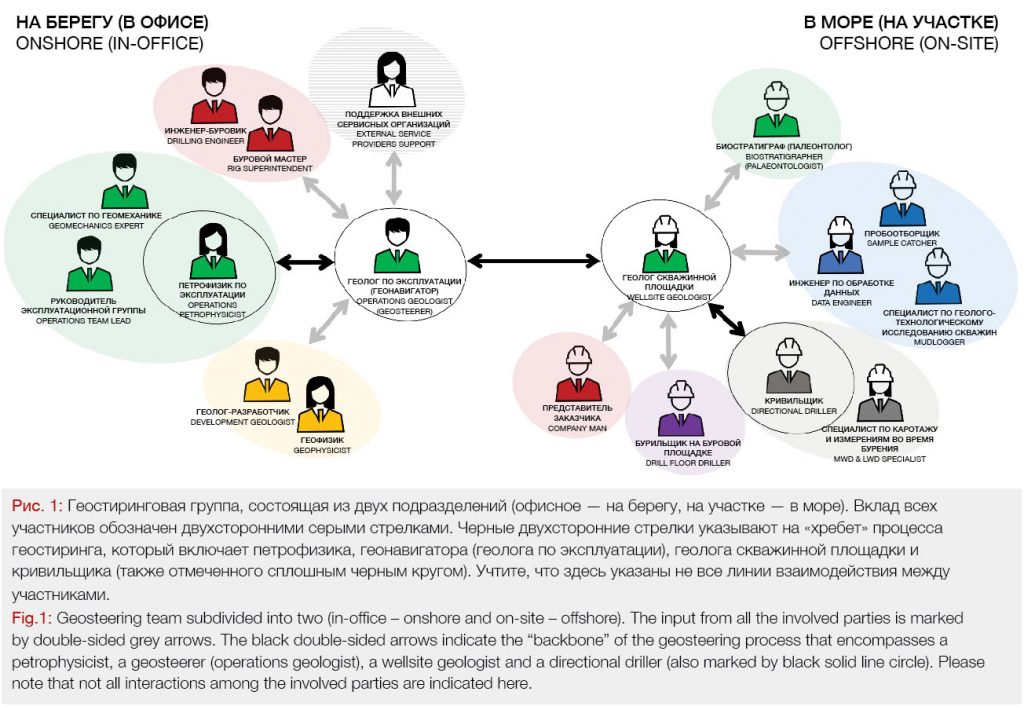

Members of Cross-Functional Geosteering Team

A geosteerer cannot perform optimally without the support of the entire multidisciplinary team. Depending on the operator, its internal work processes, country and region, or type of well/operations or even geographical location (onshore/offshore), the geosteering team setting varies significantly. Although the ultimate decision on inclination change is made by the geosteerer who is usually located in-office, a set up with a geosteerer located on-site also exists especially in onshore horizontal drilling.

Still, in generic terms a geosteering team consists of:

In-office (onshore):

• Operations geologist / geosteerer

• Operations petrophysicist

• Development geologist

• Rig superintendent

• Drilling engineer

• Geomechanics experts

On-site (offshore):

• Wellsite geologist

• Data engineer

• Mudlogger

• Sample catcher

• Biostratigrapher/palaeontologist

• Directional driller (DD)

• LWD & MWD specialists

• Driller (drill floor)

• Company man

The collaboration of all and each of the above-mentioned parties is of the utmost importance and a successful geosteering process will depend mostly on how well they communicate, share information and data, and how they influence each other’s decisions.

It is impossible to list every single role and function that affects and supports the geosteering process even on the smallest scale. They are not included here for the purpose of simplifying this article.

Factors Affecting Collaboration

With the higher speed of drilling wells, it has become crucial to establish the most optimal collaboration pattern within the cross-functional group of professionals responsible for geosteering.

By definition, the collaboration of team members is a process of working and acting together to achieve a common or mutual objective or goal, as opposed to working in competition for the benefit of an individual/s within the team. Hence, this description should also apply to the geosteering team regardless of how many members, parties, departments, roles and functions participate in the process and their location (offshore/onshore).

Collaboration components include communication, information and data sharing and making choices collectively in order to perform a task(s) that leads to achieving the common goal of optimally placing a horizontal well.

Consequently, all factors that enhance communication and data sharing and improve speed of effective and efficient decision-making will also enhance collaboration. Based on this, four main components of collaboration within the geosteering teams have been identified.

Enhanced collaboration will be a result of following:

• Shared KPIs

• Optimal geosteering organizational set up

• Lean collective decision-making process

• Virtual team concept with suitable communication tools

Shared Key Performance Indicators

As per the collaboration definition, working towards a common goal is vital for the ultimate success of the geosteering process. However, since many members of the team are placed in various departments reporting to various managers, their goals, objectives (and key performance indicators – KPIs) are often different. Commonly, the team members tasked with drilling wells (and geosteering them) are frequently judged on conflicting performance metrics. The most fundamental obstacle comes from clashing KPIs of what is commonly known as the Subsurface department and the Drilling department.

The geosteering/operations geologist (that usually belongs to the Subsurface department) is commonly measured on how much of the geosteered wellbore is placed within the pay zone (“sweet spot”). This requires precision in inclination changes, real time data analysis, multiple calculations e.g. of the apparent formation dip, and many other decisions that simply take time. This also applies to the wellsite geologists, biostratigraphers, and petrophysicists who work directly for the Subsurface team regardless of being located offshore or onshore.

Contrary to that, the rig superintendent, drilling engineer and company man are typically rewarded for bringing a well in under the estimated time and cost to drill – what translates to “as fast as possible” (apart of the most critical objective – the safety of the operations).

While the team members each have a common goal of drilling a well, their jobs have very different metrics which are usually at odds with each other. It does not require an explanation that ultimately only wells placed in the “sweet spot” and drilled “fast” are profitable and those wells that were drilled “fast” (as per drillers KPIs) yet placed outside of the pay zone are of no benefit to the operators (benefiting the drilling department only short term). It is time for Drilling departments of the entire upstream oil and gas industry to strike a balance for shared KPIs.

To add to the complexity of the situation, all external service providers, which belong to a different company and report to different managers are also potentially driven by different KPIs. It is not surprising that MWD & LWD service provider benefit from operators utilizing the most expensive hi-tech tools from their portfolio and from their tools beings used (below the rotary table level) for as long as possible. This again will be quite different to a drill bit provider who would like to prove the superior characteristics of its drill bits and drill the reservoir section as fast as possible. There is a matrix of complications and various KPIs clashes with multiple external services.

That is why mutual understanding can help geosteering teams overcome the different KPIs challenges to deliver successful horizontal wells. It is time for the industry to adjust this obvious discrepancy and assign equal performance metrics to all internal and external geosteering team members.

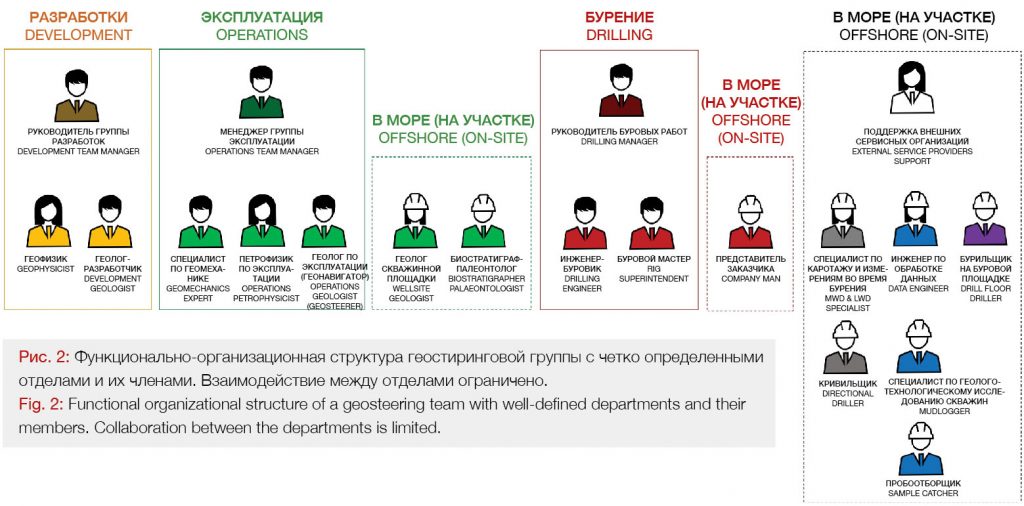

Organizational Set Up

It is difficult to operate as a team if the team members are spread across different departments reporting to different managers, evaluated based on different performance metrics and often even sit in physically separated locations (even if only separated by different floors of the same building). This normally occurs if a geosteering team operates within a functional organizational structure.

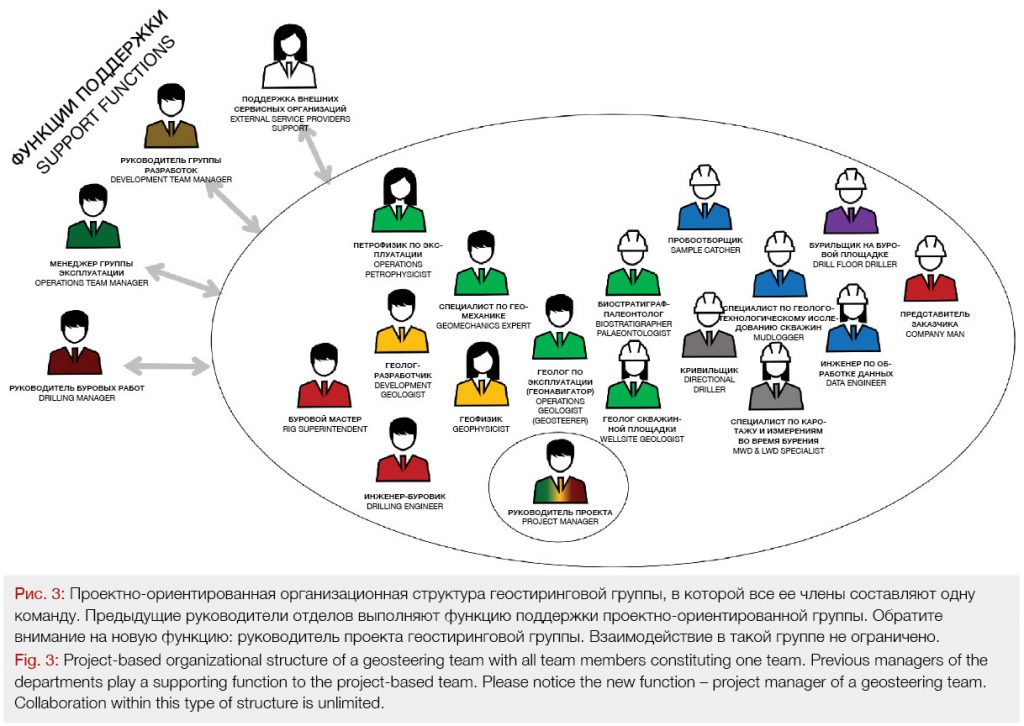

One of the possible solutions for clashing KPIs mentioned in the previous paragraph and team members’ physical separation is projectized organization. This project-based organizational structure assigns a project manager who has authority over all functions and roles of team members regardless of whether they have a drilling engineering background, or they are the Subsurface geoscientists (fig.3).

Another option for overcoming such issues is operating in a matrix organizational set up and many operators have already taken onboard this still relatively new concept in the industry (fig.4). It is an intermediate structure between functional and project-based structure.

Both options allow for the creation of a multidisciplinary geosteering team that shares the same vision, mutual respect and is characterised by in depth understanding of each members’ role in a project with the goal of achieving commonly shared objective. In our case, this would be an optimally placed horizontal well (Subsurface KPIs) that is also drilled within budget and timeline (Drillers KPIs).

Although there are substantial differences in the way these two organizational types function, both of the set ups allow for better cross functional knowledge sharing. As communications are open, information moves throughout the organization with less obstruction. Transparency and shorter communication lines are two of many benefits. Because the project-based and matrix organizational structures foster better communications, the typical boundaries between traditional departments disappear, which subsequently allows for more collaboration, and an integrated decision-making process that is more dynamic and responsive to changes.

One of the most important, outcomes of the project based set up (usually under estimated by management) is the fact that the entire onshore (in-office) part of the team shares the same office area. An open space where a drilling engineer sits next to a geosteerer and a petrophysicist sits next to a rig superintendent is the most collaborative multidisciplinary set up one can imagine.

Often, a given geosteering team includes external contractors and/or outsourced personnel who usually join the project only for a particular stage of the operations. This could include any service providers office support personnel. If not handled properly, this would further affect the collaboration between all parties. It is recommended that all contractors, outsourced personnel and temporary workers are treated as full members of the geosteering team and if possible, physically sit with the team.

Lean Decision-Making Process

Geosteering is a very iterative process where the decision-making exercise might occur at every drill pipe connection (depending on the stand length – every two, three or four drill pipe joints) or even more often. Typically, the geosteering decision making process involves seven

steps (figure 5).

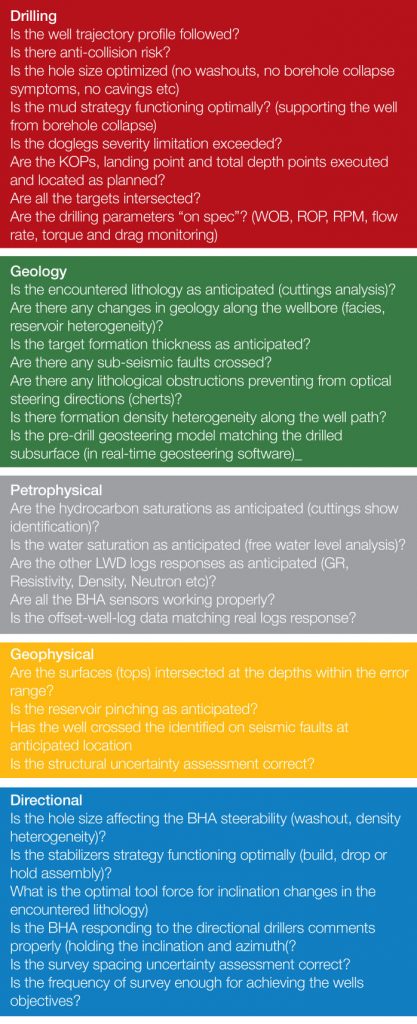

Geosteering operations involve continuously drawing inferences from real-time data that provide lagging reservoir information to predict reservoir uncertainties ahead of the drill bit. This is a base for making well trajectory adjustment decisions to optimize single or multiple well objectives. The decision-making process is repeated until the well reaches its total depth. The geosteering decisions are multifaceted as they involve gathering and analysing information from multiple sources of information (from cross-functional team members). To add complexity to the equation, later decisions are affected by previous decisions (later well placements corrections are affected by previous decisions) or states-of-nature (changes in formation properties). Each geosteering decision is made under many uncertainties, whose joint probability distributions are affected by how these uncertainties were evaluated in the previous decision stages. That is why only by applying a systematic collaborative decision process in making geosteering decisions, can one maximize value creation and make the decision-making process more efficient and effective. The geosteering decision-making process involves input from multiple disciplinary fields that can be broadly divided into five categories: drilling, geological, petrophysical, geophysical and directional. How often a decision needs to be taken depends on constantly changing input from these five categories.

Primary considerations from each field for understanding a geosteering project are mentioned below:

As already mentioned earlier, the industry’s trend is to strive for acquiring more data (and faster) believing that this is the only solution for the most optimal wellbore placement (Rajaieyamchee et al. 2010). This misperception results in development and application of more and more advanced tools (e.g. “look-ahead” tools like deep directional electromagnetic resistivity tools) which unfortunately do not fully solve the core of the problem – how to assure a quality decision-making process of where to steer that employs only the combined input from all the parties. Although the industry mainly focuses on providing data quality and detailed data analysis, the decision-making process has been shown to influence decision outcomes more than data availability and data analysis by a factor of six! (Lovallo and Sibony 2010). Although a large number of successful geosteering cases are documented and published, many studies performed on a large number of wells have shown unfavourable volumetric results which the wells failed to deliver expected productions (Saputelli et al. 2003; Rose 2004; Petoro 2014).

Instead of providing more data to analyse and performing complex data analysis, geosteering teams must ensure that a collaborative decision-making process that involves all the mentioned parties and is based on all existing data from each discipline mentioned above is implemented.

That is why, simply speaking, it is a collaboration among these disciplines that is essential to the success of the geosteering decision making process, not the extra set of data acquired with new technology.

Apart of that, each function (Subsurface or Drilling) perceives the drilling environment differently. Our brains filter incoming information based on what we are “ready” to see or what is “used” to see, thereby exposing the process to the risk of overlooking key dangers and/or opportunities. The overriding advantage of having more than one person involved in the decision process is the diversity of perspectives one gains, which provides additional insight into possible opportunities or risks. The collaboration of the geosteering team is therefore an effective insurance policy against the cognitive biases that often interfere with good judgement when relying only on the geosteerer’s intuition.

Virtual Teams Set Up

Today’s geosteering teams consist of members working in geographically distributed locations that additionally require external outsourced support groups in a country or abroad. In most cases, the mentioned decision-making process (the critical geosteering delivery path) is not limited to one physical location but requires inputs from multiple geographical dispersed sources (at least from two: onshore – in-office and offshore – on-site).

Geosteering teams operate voluntarily or involuntarily on a virtual team basis because of that geographical dispersion. A virtual team as per definition is a group of individuals who work across time, space, culture and organizational boundaries. The virtual team members are committed to a common purpose, have interdependent performance goals and shared approach to work for which they hold themselves accountable. Most importantly, they perform their tasks in a virtual work environment created and maintained by means of IT and communication software technologies. Hence, it is of the utmost importance to possess sufficient tools to support the virtual team way of geosteering.

The collaborative decision-making process mentioned in the previous section can be a lengthy process if adequate communication tools are not available. With parties located in various (at least two) physical locations, the availability of the proper communication tools becomes critical. While email or phone may be the most efficient method for basic statements, they are extremely inefficient for discussing complex geosteering decisions, providing multilayer explanations or sharing data. With continuously increasing complexity and speed of the geosteering process, the only sustainable way of communicating is the introduction of an integrated collaboration environment (ICE) to all geosteering teams.

The ICE is an environment in which a virtual team (geosteering team) can operate at its best. Such environments allow geosteering teams to realize a number of competitive advantages by using their existing computers and network infrastructure for team members’ collaboration. This environment combines characteristics of the most effective and efficient communication: desktop videoconferencing, virtual team meeting rooms and instant message into a single easy-to-use, intuitive environment. Recent developments have also allowed operators to include streaming in real-time from any rig’s location to in-office environment and archived modes into their ICE.

The most obvious obstruction of working on a virtual team basis is of course, the lack of face-to-face interaction. The importance of face-to-face meetings cannot be stressed enough. They facilitate a better understanding of interacting parties through non-verbal cues and body language. Conversations in these situations also tend to be lighter, therefore, presenting new opportunities, along with the fact that different social interactions take place during such meetings. That is why communicating through video conference system allows one to see the subtle emotions and facial expressions which you might otherwise miss.

Conclusions

For all geosteering methodologies, what is known precisely, is limited and randomly located along the wellbore trajectory. When geosteering is required, there is certainly no substitute for geologic and engineering knowledge of the area being drilled, the critical ability to approximate reality sufficiently well and to make informed directional steering decisions based on cross-disciplinary information. Therefore, the human aspect of the geosteering process should never be forgotten or underestimated. Regardless of the most advanced tools used for geosteering, the ultimate and most crucial question whether to steer up or steer down will always only be answered by a geosteerer fully supported by the geosteering team. This is where collaboration is paramount.

The solutions for improving a geosteering teams’ performance (meaning: geosteering faster) is not necessarily with a new tool or logging technique but through improving collaboration and cross disciplinary understanding. It is fundamental for the geosteering team members to solve aspects such as knowledge gap, awareness of team members’ motivations and performance metrics. If the whole team is working from a point of understanding and knowledge of the other members’ goals and limitations, it is more likely to agree to sacrifice a little to bring in an overall successful well drilling.

Most operators do not realize the strategic benefits of their investment in collaboration. These include alignment of goals and objectives within the most suitable organizational structure, decision making process designed to improve sharing of knowledge and skills across the work force and increased work-force performance with utilization of virtual team communication tools. To realize the full potential of these collaboration investments, companies need to onboard not only new innovative technologies but also new innovative ways of working together.

There is a lot at stake and there is no time to spare. Optimizing well placement through enhanced collaboration could significantly improve future production and reduce field development costs which, consequently, lead to important contributions in economic returns from the horizontal wells. This is what the oil and gas industry needs the most at the moment.

For Part Three of this article click HERE

About the Author

PIOTR PRZYBYLO has acquired crucial technical and business skills that enabled him to drill some of the deepest and longest wells in the world. He bridges the gap between the technical and commercial sides of the upstream oil and gas industry. He is the Founder of GEOMODES, a company that educates future experts in the field of geosteering and optimizes team organizational structure for efficient skill utilization. He is also the author of HORIZONTAL WELL GEOSTEERING GUIDELINES (Amazon)- first ever published comprehensive manual which is a must-have for every geosteering expert.

Reach out to author: piotr.przybylo@geomodes.com

References

• Customer stories, Microsoft, 2018. Employee engagement soars as Shell energizes internal communication with Office 365. Retrieved from https://customers.microsoft.com/en-au/story/royal-dutch-shell-mining-oil-gas-office365

• Frost and Sullivan, 2006. Meetings Around the World: The Impact of Collaboration on Business Performance. Technical report, Frost and Sullivan, Verizon Business and Microsoft, Retrieved from http://www.frost.com, 2006.

• Lovallo, D. and Sibony, O. 2010. The Case for Behavioral Strategy. In McKinsey Quarterly (March).

• Nordsøfonden, 2019. Successful development of the Tyra Southeast field. Retrieved from http://www.nordsoefonden.dk/en/article-successful-development-of-the-tyra-southeast-field

• Petoro, 2014. The cost challenge on the NCS. Petoro AS, Retrieved from https://www.petoro.no/The%20cost%20challenge%20on%20the%20NCS.pdf

• Rajaieyamchee, M.A., Bratvold, R.B., and Badreddine, A. 2010. Bayesian Decision Networks for Optimal Placement of Horizontal Wells. Paper SPE 129984 presented at the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 14–17 June. http://dx.doi.org/ 10.2118/129984-MS.

• Rajaieyamchee, Mohamad Ali, and Bratvold, R.B. 2010. A Decision Analytic Framework for Autonomous Geosteering. Paper SPE 135416 pre- sented at the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September. http://dx.doi.org/10.2118/135416-MS.

• Rose, P. R. 2004. Delivering on our E&P promises. The Leading Edge 23 (2): 165-168. Retrieved from http://dx.doi.org/10.1190/1.1651465.

• Saputelli, L., Economides, M., Nikolaou, M. et al. 2003. Real-time Decision-making for Value Creation While Drilling. Paper SPE 85314 presented at the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 20–22 October. http://dx.doi.org/10.2118/85314-MS.

Author: Piotr Przybylo