Horizontal Intervals Isolation Using Packer Bridge at the Severo-Komsomolskoye Field

SevComNeftegaz LLC

P.A. Likhachev LikhachevPA@skn.rosneft.ru

B.I. Khusainov BI_Khusainov@skn.rosneft.ru

P.V. Leontiev PV_Leontev2@skn.rosneft.ru

WORMHOLES R&D LLC

O.N. Zhuravlev ozhuravlev@wormholes.ru

A.V. Gribanov agribanov@wormholes.ru

A.M. Suvorov asuvorov@wormholes.ru

The economic effect of the introduction of this technology turned out to be very significant. One installation of the packer bridge made it possible to replace 3-4 cycles of traditional cementing, which led to a 40% reduction in costs and a 70% reduction in downtime. As a result, the estimated oil production rate of the well increased by 15-20%, which makes the technology extremely attractive for industrial applications.

Thus, a paker bridge based on cup systems has shown its effectiveness as a comprehensive solution for isolating horizontal intervals. Its key advantages – the ability to work in difficult conditions, including production pipes with a diameter of 88-106 mm, the ability to continuously monitor the condition and significant economic benefits – allow us to consider this technology as a new standard in repair and insulation work. Its application is particularly promising in fields with high watercuts, where traditional methods of cementing demonstrate limited effectiveness.

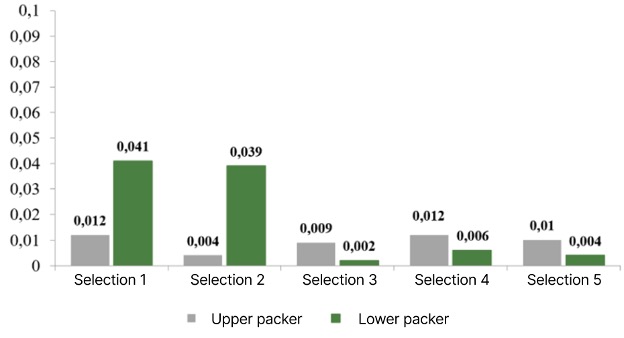

An important advantage of the work carried out is the ability to control the tightness of the layout. The built-in marker cassettes allow you to monitor the insulation condition in real time, which is especially valuable for horizontal wells, where traditional diagnostic methods often give unreliable results. After installation, the system takes two days to reachoperating mode, but then ensures stable operation for a long time. These studies, along with previous work carried out inthe framework of industrial applications, have shown the possibility of effectively using leakproofness monitoring technology to control borehole insulating equipment of various designs.