The Importance of Technological Process Validation in Pipe Manufacturing

Julia Gutorova, «Temerso-Engineering» LLC

Validation of Technological Processes in Pipe Manufacturing is a critically important set of activities aimed at proving the stability and reproducibility of seamless pipe production processes to ensure the product consistently meets the strict requirements of standards (API, ASTM, GOST, ISO, and others) and customer specifications. Errors at this stage may lead to pipeline accidents, equipment failures, and environmental disasters. To put it simply: validation is the process of confirmation through the collection of information and evidence of product compliance.

Let’s examine the specific aspects of validation in pipe manufacturing:

-

High product criticality: Pipes operate under pressure, in aggressive environments (hydrogen sulfide, carbon dioxide), and at extreme temperatures.

-

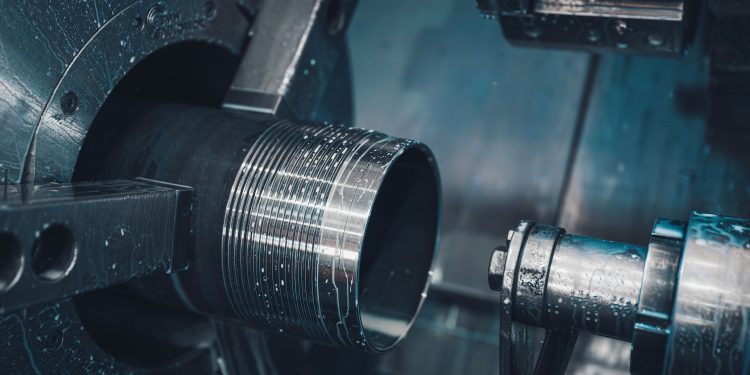

Complexity and multi-stage nature of processes: The processes include many stages (rolling, piercing, drawing, heat treatment, end upsetting, cutting), each of which affects the final properties.

-

Dependence on raw material: The quality of the starting billet significantly affects the outcome.

-

High requirements for geometry and mechanical properties: Special characteristics include wall thickness, ovality, curvature, tensile strength, yield strength, impact toughness, and hardness.

-

Non-destructive and destructive testing methods: These are mandatory parts of both the process and the validation.

It is important to understand that the validation process is closely tied to the risk-oriented thinking of the manufacturer. A clear example is the Deepwater Horizon man-made disaster, where cost-cutting at the design stage led to catastrophe. It should be emphasized that validation is not an expense but rather a kind of insurance. Failing a pipeline contract due to certification issues is more expensive than three validation batches.

Validation of technological processes is not just a bureaucratic procedure but a necessity for safe, high-quality, and economically efficient production.

Let’s look at the key reasons for its critical importance:

-

Guarantee of product safety. An unvalidated process can produce defects that even control methods might not catch. In pipe manufacturing, this implies the risk of pipeline rupture under pressure, with consequences such as disasters, fires, human casualties, and environmental damage. Validation proves and confirms that the process consistently produces safe pipes that meet all geometric and property standards.

-

Ensuring stable product quality. Validation confirms that the process reproducibly produces products that meet all regulatory and specification requirements. This is the foundation of customer trust and the manufacturer’s reputation. It provides confidence that the pipes will withstand design loads throughout their service life.

-

Reducing the risk of nonconforming products. Detecting defects at later stages leads to high costs for rework, disposal, compensation, and, most importantly, irreparable reputational damage. Validation minimizes these risks by proving the process’s capability before mass production begins.

-

Compliance with regulatory authority requirements: Rostechnadzor and certification bodies for API, GOST, etc., require evidence of validated processes. Lack of validation leads to registration and certification refusals, fines, and bans on production/sales.

If an audit during a technological process validation check reveals violations or missed scheduled validations at one plant of a multi-plant company, the audit results can trigger a ban on the shipment of unvalidated products. This ban is also applied across all other enterprises in the group, highlighting the seriousness of not conducting timely validation.

At Temerso, special attention is given to the certification and validation process. During validation, the required documentation package is prepared, including certificates, attestations—everything needed to confirm compliance with the technology. The evidence base is built on reproducibility and capability index calculations, confirming the process’s stability under the technology that ensures compliance with standards. A normality diagram also demonstrates that the process will remain within limits going forward. This method of process confirmation provides a solid foundation for customers who can be confident in the product. The application of index calculation tools for each validated parameter is a modern way to prove and demonstrate the process’s functionality and correctness.

Validation transforms “this is how we’ve always done it” into “we’ve proven it.” This is a shift in paradigm—from craft to science.